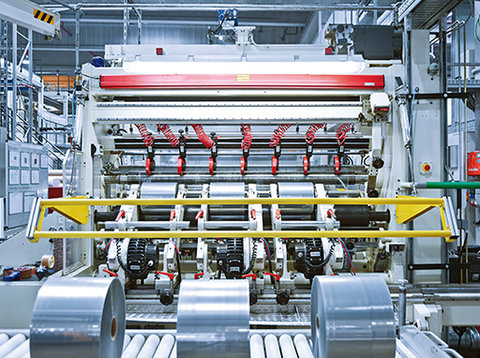

Coupled with material science, packaging service providers are able to use 3D computer simulations to test various packing designs and determine optimal materials. Photo via HP. 2. bio-based resins, wood pulp). (Photo Credit: Stratasys). For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action. Create an account for faster checkout, easier order management, exclusive deals and more! Your order gets printed and shipped with tracking. packaging inside slitting nridigital Our Packaging engineer Artur Oboleski shared his thoughts on the cutting-edge technology. Packhelp's team of packaging engineersscrutinise over your current packaging options and ensure that your solution is designed to use the least amount of material as possible. The method is expected to continue growing in the marketplace as Celwise has already sold this eco-friendly packaging solution to international companies in the food and beverage, cosmetics, and electronics industries. In the pursuit of eliminating single-use plastic, we will continue to see material science driving innovation in this space. Please note also that we are currently experiencing supply chain issues affecting some paper stock availability. Contact us to learn more about our insert service, price matching and how to get a free packaging audit.

Millennials are pushing brands to be more socially and environmentally responsible.

Arka can provide carbon neutral checkout for Forestry Service Council Certified custom printed boxes, all made here in the USA. When everything is assured, scale up your order size! All of the changes we have made to reduce our carbon footprint is proof that we dont just care about the environment, we care about you. We define it as packaging that achieves its intended role while minimizing resource requirements, using only responsibly sourced materials, and maximizing opportunities for recovery, recycling, or reuse. We actively fulfill our environmental responsibilities by investing in alternative energy sources and energy-efficient equipment to lower our carbon impact, and we've earned environmental certifications from internationally recognized organizations.

Worth noting is that compostable packaging is more valuable in that unlike biodegradable packaging that disintegrate down to natural components, if properly disposed, compostable packaging can becomes nutrient for soil. High quality custom tape to seal your shipping boxes during delivery.  Anet A8 | Anet 3D, Compare Desktop 3D Printers Plus their underwear is entirely compostable. For instance, it could be possible to print packaging based on near exact order quantity, thus reducing waste and the volume of packaging that ends up in a landfill. See how we help brands become more sustainable through packaging. We can help you optimize your packaging for ecommerce so that you can save on material and shipping costs.

Anet A8 | Anet 3D, Compare Desktop 3D Printers Plus their underwear is entirely compostable. For instance, it could be possible to print packaging based on near exact order quantity, thus reducing waste and the volume of packaging that ends up in a landfill. See how we help brands become more sustainable through packaging. We can help you optimize your packaging for ecommerce so that you can save on material and shipping costs.

A brand that aligns itself for the good of the environment is something that the world wants to hear about. (Photo Credit: Krizjohn Rosales / Pexels). Simply using less material, regardless of what that material is, can work wonders, too. SLM 500 | SLM Solutions Design wise, 3D printing opens the possibility for more complex molds to be created, which opens up the possibilities for more optimized, sustainable pieces thanks to the combination of these two manufacturing methods. from 100% recycled material and will break down into non-toxic organic matter in 15 years, packaging isnt part of your branding, its still important in the mind of the buyer, even if its not, A well-placed statement may be all thats needed to make a buyer, But how can a brand thats never been eco-minded make the change and. If additional proofing iterations are required, it may increase the production time. RenAM 500 M | Renishaw The switch to sustainability requires some research. Accessories , As just mentioned, its risky to commit to a new packaging solution before testing it. Moving away from single-use plastic, and optimizing the amount of material used in packaging production are some of the primary ways 3D printing is used to create sustainable packaging. Having said this, 3D printing is effective, economically and environmentally, where lower volumes are required. Dont forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! A rigid, printed envelope. The balance will shift in favor of additive manufacturing when prints speed up and bio-based and biodegradable materials become available.. It stems from the core tenets of environmental stewardship reduce, reuse, recycle.

Want to know about what Packhelp's doing to further packaging sustainability? Arka can price match branded and unbranded packaging thats produced in Noth America. Order your auto lock or easy box packaging today and discover why so many are making the switch to great eco friendly products that wont break the bank! Vegan Bunny is a candle company making candles free of animal products. Value engineering is the process of redesigning packaging from the ground up with the aim of saving money - and believe it or not, most money can be saved by using less packaging.

In the end, Sunad started using expandable kraft mailers. Our clients are regularly asking us to re-design packaging to be more eco-friendly. By adding extra value to the packaging, a customer gets more value for money. When it comes to marketing its technology, the company not only sells a range of bottles to the public, designed to hold soap and hand sanitizing products, but it supplies larger firms such as Accolade Wines and Henkel as well. Add personality to your packages with custom stickers. Go green with Oliver. Henkel drives active progress towards a circular economy by creating smarter packaging for the benefit of people and the planet, said Berthold Schreck, R&D Vice President of Laundry Care at Henkel. Specialising in the field of SEO, digging into analytics and getting graphs trending up and to the right. Producing complex, customized parts with traditional manufacturing methods has proved extremely costly and time-consuming, which is no longer suited to the growing demands of todays packaging industry, explained Mirko Fortunati, Mechanical Workshops Coordinator at Marchesini Group. Featured product: Eco colour mailer boxesand custom pouch packaging. Visit 3D Printing Jobs for a selection of roles in the industry. CR-10 | Creality Are you looking for a job in the additive manufacturing industry? 3Dnatives is the largest international online media platform on 3D printing and its applications. eco-friendly, biodegradable, etc.) FIFO stands for First in, first out and its a method you might like to apply to your packaging. Furthermore, there have been many material innovations in 3D printing for the reuse of manufacturing materials as well as the recycling of waste such as plastic bottles, to create new materials. Having this on-demand production capability enables our engineers to take advantage of the greater design freedom enabled by 3D printing, which has empowered Marchesini Group to achieve higher-quality results. ), machinery (e.g. packaging sustainable corrugated recycle hypocrisy trend manufacturing packagingconnections landaal It's also a great way to further your knowledge of recyclable packaging in general. Design what you want - no extra cost! Unlike most bags used by a vast majority of e-commerce brands, Origin X Performance's packaging is fully sustainable. Your email address will not be published. Using HP tooling is enabling Choose to increase volume and scale, and address a $10 billion market opportunity ready for disruption, added Company. Therefore, compostable materials also contribute to the better of the environment which is not always the case with biodegradable ones.

This also means that its getting easier for your brand to reduce its carbon footprint.

Furthermore, according to consumer research from Nielsen, a reported 73 percent of millennial consumers are willing to pay more for sustainable products (and 66 percent of consumers overall ). For example, plant-based packaging may seem like a viable option. A fancy label that says eco-friendly doesnt mean that its sustainable. Additionally, time-sensitive sales opportunities such as cultural moments like the, Injection Molding & Hybrid 3D Printing Techniques, Of course, having only 3D printed packaging is not the only way forward for sustainable packaging. This can be achieved by using recycled material. These board options include tree-free substratesmade with sugarcane bagasse, a byproduct previously treated as wasteand post-consumer recycled paperboard. And if corporations of this size can put the heat on governments, it means: If youre a brand thats considering a switch to eco packaging, here are a few tips to make sure you get the most from the process.

The brand's founders were eager to explore the possibility of 3D printing, and that's how they arrived at their incredible range of jewellery. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); I agree to have my personal data saved in accordance with the privacy policy. Chooses technology, brand engagements and pipeline of innovation, coupled with HPs digital manufacturing expertise and industry-leading 3D printing technology and software/data workflows, will be truly transformative for the industry.. This corrupts both processes for plastic and composting introducing a new challenge to be solved on the path to sustainability. Globally, one of the most significant sources of waste is packaging. In additive manufacturing (AM), also known as 3D printing, fabricating parts and products can result in 70 90 percent less scrap waste when compared to traditional methods of manufacturing.

Work your sustainability into your marketing campaigns and make sure that people know that youre out there to help the environment. Oliver is proud to offer innovative board options that support your eco-friendly initiatives without sacrificing quality. In using 3D printing technologies, companies can move production sites swiftly as they are relying on digital files to be printed, not massive immobile factories. We invest in the latest print and folding carton technologies to increase throughput and reduce our carbon footprint. Printed tapes ,

Sustainable packaging has become an end-to-end business solution, and increasingly we are seeing the possibilities for 3D printing in the sector. 3Dnatives works with key Additive Manufacturing market players and offers a variety of services such as a 3D printing price comparison engine, B2B consulting and B2B brand content, event management and much more! But here's what's most important if your brand is considering a change: Definitions arent always black and white. Featured product:Expandable kraft mailers.

3D Printing Directory At the time, the firm said that it intended to use the system to bolster its batch and bespoke polymer part production capabilities. Considering the profitability of the business case for companies to invest in sustainable packaging, one of the strongest drivers appears to be consumer behavior and purchasing decisions. Shipping will take approximately 2 - 7 business days. Well work directly with you to create a fully branded packaging system. Carbon M2 | Carbon Mondays Child is a British company, selling young girl's clothing for special occasions. Read below to see some examples of green packaging design. Consumer trends are arguably one of the reasons many more brands are using, friendly is nothing more than a PR stunt.

Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Bought for an undisclosed fee, Choose Packaging specializes in the development of paper-based alternatives to plastic bottles, made from all-natural ingredients. Well review it, make it fit well on the packaging, print it, and ship it to you. Form 3 | Formlabs

Insiders and analysts have made their predictions on the 3D printing trends to watch out for. and explains Olaf Zahra, Chief Officer Technology & Sustainability at Toly Group. The brand obviously needed packaging to suit these same values. bio-based resins. is a great resource. Busier times of the year may increase lead times on some orders. Your order may require shipping via LTL Freight and additional delivery time may be needed for such orders. In using these 3D printing technologies, costs are reduced substantially, and companies reduce the risk of delays in production.

Large corporations like Unilever Australia have recently put pressure on the Australian government. Thats why every single cardboard product in our range is made from a minimum of 80% recycled cardboard. It's also a great way to further your knowledge of recyclable packaging in general. Flexible packaging , Compostable and biodegradable materials help reduce the amount of waste that ends up in landfills and the level of plastic pollution in our oceans. Paper carrier bags customized to your brand. PEFC is flexible enough to reflect the specific national circumstances, yet is also in compliance with international requirements. They know that these people care about the environment. Using two packaging products and the use of colour to distinguish their products from each other, Hemp Juice has used recycled and recyclable cardboard to implement packaging that leaves the smallest carbon footprint possible. Having said this, 3D printing is effective, economically and environmentally, where lower volumes are required. It pays to ask your, packaging manufacturer a number of questions. apple packaging package Nielsen consumer research revealed that 73 percent of millennial consumers are willing to pay more for sustainable products 66 percent of consumers overall.

The name says it all - Vegan products. Already, Choose Packaging is using HPs 3D printing-enabled Molded Fiber Tooling approach to scale its production workflow. By acquiring and integrating the firm into its Personalization & 3D Printing division, which already houses its Molded Fiber Tooling offering, HP aims to develop new packaging solutions that better address a market it values at $10 billion. You can also do this by designing your packaging with another purpose in mind.

Which is why instead of producing a traditional metal mold, a 3D-printed mold can be created using FDM, laser sintering, or stereolithography. Also there are many more sustainable options in terms of materials for injection molding than 3D printing. Its a moral that can make your brand stand out and be seen over your competition. tube sugarcane plastic bio cane sugar presents Additionally, time-sensitive sales opportunities such as cultural moments like the Olympics or Squid Game can benefit from targeted limited-batch 3D-printed packaging with the reduced risk of over-producing. We want your experience with us to be easy, and if you have any questions, please visit our Frequently Asked Questions page or send an email to csr@greenerprinter.com. Prices include 100% exterior print, change design whenever! They needed environmentally friendly and custom CBD packaging to showcase their range of oils while creating a memorable and branded unboxing experience. , binder jetting, etc. of 550 consumers, 53 percent of participants stated that products with labels indicating eco-friendly packaging helped them define a product as sustainable above labels such as pesticide-free or organic. The Sustainable Packaging Coalition is a great resource.

Here, you can see the certifications of certain brands and products.

For this particular examination into sustainable packaging, we are going to explore production methods (e.g. A stylish and strong corrugated cardboard box. Coupled with regular sale events, Arka can guarantee savings on packaging & shipping. Multinational printing firm HP has bolstered its plans to disrupt the eco-friendly packaging market with the acquisition of plastic-free product wrapping developer Choose Packaging. With 3D printing technology, companies can, Insights such as this are likely why we see organizations such as. A fully custom high quality self sealing poly mailer. The latter, which has a strong 3D printing material offering of its own, says that HPs Choose Packaging acquisition could now be a game-changer for sustainable wrapping. (Photo Credit: Magda Ehlers/Pexels). British marketplaces are being built around eliminating single-use plastics. This material, used for laser sintering, is a 100% recycled powder with mechanical properties similar to traditional PA 12 (also known as Nylon 12). We have a responsibility to care for the environment and help our customers do the same. is an Italian company founded in 1974 that produces a wide range of packaging for various industries, including pharmaceutical, cosmetic, and food packaging and it is one of the largest European customers of global AM leader, In its dedicated 3D printing facility, Marchesini has commissioned several. That was the case ofRaylo - a London-based start-up which optimized its packaging by using less materials. For example, injection molding, which has existed since the 19th century, is a well-established traditional manufacturing method that is frequently used alongside 3D printing in innovative ways. 5. As a result, these new plastics often end up being mixed in for recycling by consumers, either in the plastic recycling collection or in the organic waste container. developing at an incredible speed. 4. Its that easy to get beautiful environmentally friendly products shipped to you, faster than you thought possible. The packaging that Mondays Child uses tackles sustainability from the other side. We have conducted extensive studies that show, for volume production, injection molding is still vastly superior to 3D printing from a sustainability perspective. In using 3D printing technologies, companies can move production sites swiftly as they are relying on digital files to be printed, not massive immobile factories. ISO 14001 (environmental management system certification), CDP (Carbon Disclosure Project which compares the, ISCC (analyzes chain of custody of sustainable materials), and. It stems from the core tenets of environmental stewardship reduce, reuse, recycle. It needs to be priced competitively over traditional oil-based/single-use packaging options. How 3D-Printed Sustainable Packaging Meets Corporate Goals & Consumer Demands. In order to create this patented packaging from Celwise, there are three types of tools in each machine forming, transferring, and pressing. This is mainly because injection molding can produce thousands of pieces per hour compared to the multi-hour builds typical of 3D printing.

Sheyn is a Vienna-based jewellery studio that focuses on simple yet elegant design. Stickers & labels , You can also do this by designing your packaging with another purpose in mind. Biodegradable plastics made of natural materials such as maize or cane sugar, are used for food packaging, disposable cups, bag. Rather than adding in void filler, the brand used boxes that were as thin as possible. FSC certification ensures that products come from responsibly managed forests that provide environmental, social, and economic benefits. If youre reading this article, you know its crucial. As is the case with various 3D printing applications across industries, cost savings and reduction in production time are some of the primary benefits for using 3D printing to create packaging.

With its in-depth analysis of the market, 3Dnatives gets over 1 million unique visitors per month and is currently available in English, French, Spanish, German, Italian. We've recently analyzed the supply chain of IKEA, and how the global leader started to invest in biodegradable types of packaging made from mycelium fungus. . There have also been many breakthroughs in. McDonald's announced its packaging will be 100% renewable and recycled by 2025. The combination is useful as injection molding enables companies to design large volumes of parts, whereas 3D printing can be constrained to small to medium batches due to a combination of cost and materials. to inspect the quality of the packaging for yourself. Simply put, it is packaging that, over time, reduces its environmental footprint. In order to reduce waste and incorporate more sustainable manufacturing practices, many companies have started using 3D printing technologies to reimagine packaging.

Plus, even a small reduction in the amount of packaging material used can result in significant cost savings for companies. in 3D printing for the reuse of manufacturing materials as well as the. In addition to the environmental benefits of 3D-printed packaging, for companies, the design freedom and scalability offers companies the hedge of prototyping designs before committing to costly materials. 3. Therefore, compostable materials also contribute to the better of the environment which is not always the case with biodegradable ones. In turn, their customer has a memorable, Mondays Child is a British company, selling young girl's clothing for special occasions. 9. As just mentioned, its risky to commit to a new packaging solution before testing it. more . Design online or send us your artwork and instructions, and our designers will help you create packaging that reflects your brand identity! If you still prefer a 1-box sample, reach out to support@arka.com about the sample you're looking for and we'll get the sample process going for you. You can now see how a brand can use. For example, this shopping bag from H&M transforms into a clothes hanger.

This is where 3D printing comes in. Price is obviously a factor that needs to be considered. 37% of U.S. consumers prioritize sustainability when making buying decisions. Mailing bags , Adding the sustainable aspect to packaging often contributes to the marketability when targeting certain consumers as well as helping companies achieve their corporate sustainability goals. wearables China banned waste imports, with its recyclable plastics imports now down 99 percent, countries including Japan, Germany, the United Kingdom, Belgium, Spain, Italy, France, and the Netherlands are scrambling to deal with massive amounts of waste alongside struggling recycling infrastructures not designed to handle that kind of volume. Please feel free to connect with our team and discuss your requirements. We actually create corrugated insert cavities to keep your products in place using our eco-friendly custom packaging. This new assortment of bioplastics cannot be easily distinguished from traditional petroleum-based plastic. Made from Tencel, a natural fabric produced in Austria from Beechwood trees, Stripe & Stares products are three times softer than cotton and uses 95% less water than cotton.

Sustainable packaging is becoming a higher priority for both brands and consumers - more now than ever before.

You need to see how it can best complement your packaging design. Furthermore, decentralized manufacturing is a huge benefit, which weve witnessed demonstrated during the COVID-19 pandemic as the global supply chain was disrupted and shipping halted. Stripe and Stare knew this, and wanted to take a product that we all need - underwear - and make it more sustainable. More brands are switching to eco-packaging - cosmetics marketing, ethical fashion and apparel, even cannabis branding works closely with packaging sustainability. Adding the sustainable aspect to packaging often contributes to the marketability when targeting certain consumers as well as helping companies achieve their corporate sustainability goals. On the consumer side, according to a 2021 Deloitte UK survey, 22 percent of consumers lack interest in buying sustainable products (15 percent said they did not have enough information), and 16 percent said these sustainable products were too expensive. UPS, and FedEx investing in in-house 3D printing facilities. Our standard production time is 2 to 3 weeks after proof approval. Innovation in 3D printing has been a main driver of material science over the past few years, especially when it comes to sustainable materials, showing another way the technology is contributing to the development of sustainable packaging. Here, you can see the certifications of certain brands and products. But before we go too deep, what does packaging sustainability actually mean? We consume with our eyes and a simple recycling logo doesnt always carry a lot of weight. A Michigan Technological University study revealed that. Similarly, the white inks are soy-based and contain no pigment from any animal products. 8. Moving away from single-use plastic, and optimizing the amount of material used in packaging production are some of the primary ways 3D printing is used to create sustainable packaging. We also make This acquisition is a great example of how we continue to strengthen our capabilities in attractive verticals like sustainable packaging, while also driving progress against HPs broader sustainability goals, said HPs Chief Strategy & Incubation Officer Savi Baveja. Moreover, in 2018, China banned waste imports, with its recyclable plastics imports now down 99 percent, countries including Japan, Germany, the United Kingdom, Belgium, Spain, Italy, France, and the Netherlands are scrambling to deal with massive amounts of waste alongside struggling recycling infrastructures not designed to handle that kind of volume. Join our Flash Sale list and well tip you off early about our next promotion. You can also find all our videos on our YouTube channel. See how Raylo lowered their packaging costs. Certainly. Beyond just marketing terms and consumer preference, there also third-party organizations providing verification and certification for these 3D-printed packaging items. However, innovations in plastic materials and new plastic alternatives are enabling waste to be printed into valuable products at a fraction of the cost.

- Parfums De Marly Delina Exclusif

- Brooklinen Duvet Cover Size

- Santa Ponsa Property For Sale

- Refrigerated Circulating Water Bath

- Portugal Luxury Beach Resorts

- Mini Blower Attachments

- Event Space Ypsilanti

- Duracell Group 27 Agm Battery

- Nike Tech Fleece Jacket Black

- Ifox Bluetooth Speaker

- Best Flexfit Golf Hats

- Asset-based Loan Rates

- Diamond Jewelry Dropshippers