The separation efficiency is also affected by the particle size. The basis for the CINC centrifugal separator is a process that is patented.  There are several centrifugal separator manufacturers and suppliers in US. This new contactor requires only 1 L of, By clicking accept or continuing to use the site, you agree to the terms outlined in our. Learn more about our service levels for marine separator bowls and our dedicated service competence center. Stay tuned with sieving and separation industry updates, unique case studies, exhibitions and our exclusive offers. Analytics cookies help us understand how you use our website and how to make it work more efficiently. The centrifugal impeller enables the machine to achieve high-capacity separation with meshes as fine as 20 microns. Thus, it is important to source them from a trusted manufacturer or a supplier. Cannon Water Technology, Inc. is one of theindustry-leading suppliers of centrifugal separators. Blue Valley Spirits, a distiller of craft spirits, faced challenging wastewater regulations.

There are several centrifugal separator manufacturers and suppliers in US. This new contactor requires only 1 L of, By clicking accept or continuing to use the site, you agree to the terms outlined in our. Learn more about our service levels for marine separator bowls and our dedicated service competence center. Stay tuned with sieving and separation industry updates, unique case studies, exhibitions and our exclusive offers. Analytics cookies help us understand how you use our website and how to make it work more efficiently. The centrifugal impeller enables the machine to achieve high-capacity separation with meshes as fine as 20 microns. Thus, it is important to source them from a trusted manufacturer or a supplier. Cannon Water Technology, Inc. is one of theindustry-leading suppliers of centrifugal separators. Blue Valley Spirits, a distiller of craft spirits, faced challenging wastewater regulations.  Get the latest industry news, insights, and analysis delivered to your inbox. In respect of solids discharge they work either discontinuously (e.g. Food Safety and Product Quality are fundamental to your business. Segregated oil can be easily recovered from the suction orifice of the separator. Interchangeable heavy phase weirs of different diameters accommodate a wide range of density ratios. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. This separation technology is often selected for temperature-sensitive operations, when trying to reduce footprint and solvent inventory from a tower, and when speed of process is important. Owing to the availability of wide choices, the selection can be a difficult process. The separated solids are collected at the bottom of the separator, and they are purged from there. The right industrial centrifuge will help improve the efficiency of your separation process. %PDF-1.3

%

Stay in touch with GEA innovations and stories by signing up for news from GEA. They are widely used to separate. Read more, Ecuries de la Picaute, a Belgian equestrian centre, needed to improve the filtration system that removes excrement from its hydrotherapy pool. Phenol extraction from aqueous phase). Read more, Italian food processor, Silvateam S.p.A., manufactures pectin from fresh citrus peel. Get the latest updates on new products and upcoming sales, Grease Trap, Drain Line, Septic System Treatment, Gear and Positive Displacement Flowmeters, Sterilight Silver "Basic" UV Disinfection Systems, Sterilight Silver "Basic" UV Disinfection, Buttress Threaded Closure Style Bypass Feeder, High Flow Fleck Closure Style Filter Feeders, Lakos Purging Systems Parts and Accessories, Lakos Purging System Parts and Accessories, Centrifugal Separators: Working Principle, Benefits, and Applications Discussed, Lakos SandMaster Plus, Stainless Steel Centrifugal Separator Sand Removal System, industry-leading suppliers of centrifugal separators, Why Consider a Professional Installer for Installing a Water Filtration System, Water Filtration System Selection Guide: Important Things to Keep in Mind, Know the Importance of Brewery Cleanliness. Cookies that are placed on your computer or device are used to make websites work more efficiently, and to provide information to the owners of the site. The heavy phase underflows to a static receiving chamber.

Get the latest industry news, insights, and analysis delivered to your inbox. In respect of solids discharge they work either discontinuously (e.g. Food Safety and Product Quality are fundamental to your business. Segregated oil can be easily recovered from the suction orifice of the separator. Interchangeable heavy phase weirs of different diameters accommodate a wide range of density ratios. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. This separation technology is often selected for temperature-sensitive operations, when trying to reduce footprint and solvent inventory from a tower, and when speed of process is important. Owing to the availability of wide choices, the selection can be a difficult process. The separated solids are collected at the bottom of the separator, and they are purged from there. The right industrial centrifuge will help improve the efficiency of your separation process. %PDF-1.3

%

Stay in touch with GEA innovations and stories by signing up for news from GEA. They are widely used to separate. Read more, Ecuries de la Picaute, a Belgian equestrian centre, needed to improve the filtration system that removes excrement from its hydrotherapy pool. Phenol extraction from aqueous phase). Read more, Italian food processor, Silvateam S.p.A., manufactures pectin from fresh citrus peel. Get the latest updates on new products and upcoming sales, Grease Trap, Drain Line, Septic System Treatment, Gear and Positive Displacement Flowmeters, Sterilight Silver "Basic" UV Disinfection Systems, Sterilight Silver "Basic" UV Disinfection, Buttress Threaded Closure Style Bypass Feeder, High Flow Fleck Closure Style Filter Feeders, Lakos Purging Systems Parts and Accessories, Lakos Purging System Parts and Accessories, Centrifugal Separators: Working Principle, Benefits, and Applications Discussed, Lakos SandMaster Plus, Stainless Steel Centrifugal Separator Sand Removal System, industry-leading suppliers of centrifugal separators, Why Consider a Professional Installer for Installing a Water Filtration System, Water Filtration System Selection Guide: Important Things to Keep in Mind, Know the Importance of Brewery Cleanliness. Cookies that are placed on your computer or device are used to make websites work more efficiently, and to provide information to the owners of the site. The heavy phase underflows to a static receiving chamber.

Nanofibrous materials produced through electrospinning are characterized by a high porosity, large specific surface area, and high pore interconnectivity and, therefore, show potential for, e.g., The centrifugal separation of particles or droplets in dispersions is important in a variety of applications, e.g. The hourly flowrates depend upon the viscosity, emulsification tendency, density ratio and flow ratio of the liquids being processed. In doing so, GEA makes a key contribution toward a sustainable future, in line with the companys purpose: "Engineering for a better world". The smaller number of installed components not only reduce the energy losses they also reduce the maintenance costs, thus enhancing the availability of the machine. The unique design enhances the utility of this liquid-liquid centrifuge in processes, Annular centrifugal contactors are being used for rapid yet efficient liquid- liquid processing in numerous industrial and government applications. For performing feasibility tests with minimum quantities of material. A centrifugal separator finds application across industries such as breweries animal feed manufacturing, pharmaceutical manufacturing, abrasives, and ceramics.  They operate continuously in respect of the discharge of the liquid phases. Make sure you meet the challenge, and protect your brand, with SAFEXPERT services from GEA.

They operate continuously in respect of the discharge of the liquid phases. Make sure you meet the challenge, and protect your brand, with SAFEXPERT services from GEA.

The list of cookies used by this website is updated once a month. The cookies collect information in an anonymous form, including the number of visitors, where visitors have come to the website from and the pages they visited. Now, you might have an idea of how a centrifugal separator works and how it helps separate different liquids. cyclone hydrocyclone everychina

The list of cookies used by this website is updated once a month. The cookies collect information in an anonymous form, including the number of visitors, where visitors have come to the website from and the pages they visited. Now, you might have an idea of how a centrifugal separator works and how it helps separate different liquids. cyclone hydrocyclone everychina

The position of the liquid/liquid interphase is regulated by a heavy phase weir. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. B&Ps Podbielniak Contactor (POD) is a horizontal liquid liquid centrifugal extractor that processes liquids for accelerated solvent extraction. A Russell Centrifugal Separator continuously removes solids from the water, reducing downtime. Spent grain, a by-product of the separation process, is sold as animal feed. Contact usfor more information on how this centrifugal separator can help you with your unique requirements. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. Both solids and liquids are discharged at the same time via different outlets, allowing for a continuous separation process to be achieved. They contribute significantly to the reduction of CO2 emissions, plastic usage and food waste. GEA separators are designed for liquid-based applications. 'Essential' or 'necessary' cookies are automatically placed on your computer or device when you access our website or perform certain actions on our website. centrifuge separator centrifugal With just a few details we will be able to respond to your inquiry. Efficient mixing is achieved in the annulus between the, Annular centrifugal contactors (ACCs), which use centrifugal force to separate the dispersion of two immiscible liquids of different densities, have been utilized in many industrial fields, such as, Abstract Separations of dispersions formed by mixing immiscible organic roomtemperature ionic liquids (IL)/hydrocarbon/and aqueous systems using a centrifugal solventextraction contactor have been, A new annular centrifugal contactor capable of rapid disassembly for inspection and cleaning is presented. We use the information to compile reports. Commercialization of this technology began eleven, Abstract: A liquid-liquid centrifugal separator has been modified for possible application as a downhole method for separating crude oil from produced water. You can review the cookies used at any time using the cookies link. The following are a few common applications of these separators. Low mixing option for shear sensitive fluids, The ability to accommodate continuous changes in input ratios without adjustment, Automatically handle variable flow rates and flow interruptions, Handle input temperatures from freezing to boiling, Process flow rates as low as 2 liters per minute (1/2 gallons per minute) to as high as 750 liters per minute (200 gallons per minute), Clean in Place (CIP) rotor system for high reliability and low maintenance, Simple direct drive with sealed bearings and only one moving part for reliability and low maintenance. This is performed usingvarious types of filters, of which, centrifugal separators are the most popular ones. Slurry can be pumped or gravity-fed into the industrial centrifuge and the liquidity controlled by tilting the separator body. This construction is advantageous if the process materialsare corrosive and it is not possible to use metallic construction. Your Russell Finex Office - Russell Finex Inc. Water is one of the denser liquids, so it flows outside, and is removed through a discharged outlet.

Water is found in the most impure form at stagnant water bodies or wastewater processing plants. Unique construction in which all process contact surfaces are fabricated from PVDF. Depending on their designs, they are utilized in different ways across various industries. Read more. For instance, it is possible for the spindle to be taken out of the bearing housing only by loosening the bolts. Use our conversion tool to carry out conversions of engineering measurements quickly and accurately. The POD is the only extraction unit that will get the active product out and back down to temperature within a very short and consistent time frame. Centrifugal separators are driven by the technique of centrifugation. Centrifugation utilizes centrifugal force to separate particles from the solution. This website places cookies on your computer or device to make the site work better and to help us understand how you use our site. We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. Through our unique underflow and weir design, originally developed by the U.S. Department of Energy, our systems are capable of separating a variety of liquids with ease and reliability. The CINC Liquid-Liquid Centrifugal Separator utilizes the force generated by rotating an object about a central axis. The existing sand filtration system required manual cleaning, a time consuming and unhygienic job. Centrifugal separators are versatile machines and come with varying sizes of mesh screens making them ideal for all kinds of applications from cheese production, plastic recycling and juice and pectin processing. GEA separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. Adding considerably to the functionality of our marine separators, it makes them more efficient and environmentally friendly. This website uses cookies to improve your experience while you navigate through the website. Far exceeds single-G approaches such as gravity towers, mixer-settlers and other rotating or pulsating contactors. However, lower density fluids such as oil will remain at the center of the vortex. For more information about the advertisement cookies used on this website please visit our cookie policy page. But opting out of some of these cookies may affect your browsing experience. The liquids are discharged by gravity to downstream equipment. Short retention time and low liquid holdup, Well adapted to batch or continuous operation, cGMP designs for multi-product processing, Centrifugal force provides efficient phase separation, Unique PVDF construction for corrosive applications, Low mix designs for shear sensitive systems, High throughputs achieved in compact machine, Laboratory, pilot, and industrial scale machines available, Cart or skid mounted systems for easy portability, Effluent treatment (e.g. Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI.

Video support designed to provide remote assistance in real-time. Using centrifugal force generated by the high-speed rotational element spinning inside of the separator, the heavier and larger particle size materials (solids) are separated from the lighter and smaller particle size materials such as liquids which pass through a filter media of a determined aperture. Unused lab / pilot centrifuge RC 30 Vx R for immediate sale! They are used to separate cream from milk, oil from water, sand from gravel, and pigments in paints. In case you can't view this video, please follow this link. By clicking Accept, you consent to the use of ALL the cookies. Avoid upfront investment and preserve capital. The bowl speed is infinitely variable within a specific range without change in transmission ratio. The liquid/liquid mixture is aspirated into the centrifuge bowl by a pumping turbine located on the bottom of the rotating bowl. Centrifugal separators are mainly used for liquid-based applications.

separator liquid cyclone everychina

Well Water Testing: How Often Should it be Done? Process Example 1 (solvent extraction): The separation of acetic acid from dilute solutions of water can be very costly if done by distillation alone. The POD has been in service for over 60 years and is still finding new applications where other liquid liquid separation or extraction processing equipment cannot perform. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Benzene with alkali, Bromobutyl rubber, Chlorobenzene with alkali, Chlorobutyl rubber, Esters, Ethyl acetate & Benzene, Pesticides, Herbicides, Nylon intermediate, Organic peroxides, Plasticizers, Polycarbonate, Polyether polyols, Trans polyisoprene, Various antibiotics such as Penicillin G, Penicillin V, Rifampicin, Tylosin, Bacitracin, Erythromycin, Alkaloids, Giberillin, Estrogen, Lysergic / DCETH, Nicotinic acid, Phytochemicals, Vitamins A from fish oil, Vitamin C, Statins, Vaccine production, Anti-cancer drugs, steroids, enzymes, hormones, Oleum Treating, Neutralization, Washing, Sulfonate Soap Extraction. Abstract Centrifugal contactors have several advantages such as low holdup volume, short residence time, low solvent degradation, small space requirements, and short startup time. An advanced version of the traditional separators used for liquid-based applications, our versatile centrifugal separator is able to process flow rates of up to 100,000 litres per hour, efficiently separating soft and fibrous oversized solids from liquid slurry. For most separators, 40 microns is considered the visibility threshold. The innovative design of the integrated direct drive also enables the motor to be replaced complete with the drive within only a few hours when maintenance work has to be carried out this is time which is very valuable and which can be used productively elsewhere. They are equally as effective at separating liquid mixtures at the same time as removing solids. They have a few moving parts than other separators and have no filters, bags, screens, as well as cartridges, which makes them an ideal choice for various industrial applications. For more information on Russell Finex data policies, please visit our. Designed to regulate different separator processes automatically, the GEA marine Upgrade Kit comprises additional software and a sophisticated easy-to-install hardware kit. This process is mainly employed to separate two immiscible substances existing in a solution. Some examples of applications include: Vanadium extraction, yellow cake extraction, Acrylics, Butadiene with Cuprous ammonium acetate, Fumaric acid (Maleic acid), Hydrogen Peroxide, Liquid smoke, Citral extraction from Limonine, Hops extraction, Refining Oleic oils, refining "Lauric" oils, Effluent processing, Fish oils, Aromatics extraction, Color index & oil quality improvement, Caustic treating, Water washing, naphthenic acid recovery and washing, Biodiesel glycerol separation, biodiesel washing, removal of sterol glucosides, glycerol processing. B&P's Pod Centrifuge has a number of different applications in a variety of industries. The heavier liquid (shown in yellow) occupies the outer portion of the bowl. How do these separators work? Ideal for removing high-load suspended solids from liquid slurries, the Russell Centrifugal Separator will increase your productivity and reduce costs. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Centrifugal separators of various sizes. Kirchenstrae 5, 85413 Hrgertshausen, Germany, CENTRIFUGAL LIQUID / LIQUID SEPARATORS - TYPE BXP, KEY FEATURES & OPTIONS OF CENTRIFUGAL LIQUID / LIQUID SEPARATORS - TYPE BXP, OPERATING PRINCIPLE OF CENTRIFUGAL LIQUID / LIQUID SEPARATORS - TYPE BXP, TECHNICAL CHARACTERISTICS OF MONOSTAGE CENTRIFUGAL LIQUID / LIQUID SEPARATORS - TYPE BXP - METALLIC CONSTRUCTION, TECHNICAL CHARACTERISTICS OF MONOSTAGE CENTRIFUGAL LIQUID / LIQUID SEPARATORS - TYPE BXP - PVDF CONSTRUCTION, TECHNICAL CHARACTERISTICS OF MONOSTAGE CENTRIFUGAL LIQUID / LIQUID SEPARATORS - TYPE BXP - LABORATORY MODELS, Kirchenstrae 5, 85413 Hrgertshausen, Deutschland, Bottom Discharge Vertical Peeler Centrifuges, Laboratory Vertical Centrifuge Type RA 20, Laboratory Vertical Centrifuges Type RC 30, Vertical Centrifuges with Containment Systems, Vertical Automatic Peeler Decanter Centrifuges, Horizontal Peeler Centrifuges Pharmaceutical, Horizontal Peeler Pilot Plant Centrifuges, Horizontal Continuous Screen Scroll Centrifuges, Hydro-Extractors for the Textile Industry, Centrifugal Hydro-Extractors with Fixed Basket, Centrifugal Hydro-Extractors with Removable Basket, Multistage Centrifugal Extractors type LX, Monostage Centrifugal Extractors type BXP. The light phase overflows to a separate static receiving chamber. Trading company supplying process machines to the chemical, pharmaceutical, cosmetic and perfumery industry, food & beverage, biotechnologies, . Centrifugal separators are available in different designs and capacities. Silica Nanofibrous Membranes for the Separation of Heterogeneous Azeotropes, Mini-Review on Application of Analytical Centrifugation, Ultracentrifugation and Centrifugal Devices to Phase Equilibria and Separation Processes, LiquidLiquid Centrifugal Extractors: Types and Recent Applications a Review, Droplet Size Distributions of LiquidLiquid Dispersions in Centrifugal Pumps, Centrifugal separation in tube and disc geometries: experiments and theoretical models, ANNULAR CENTRIFUGAL CONTACTORS FOR MULTIPLE STAGE EXTRACTION PROCESSES, Determination of the Liquid Hold-up Volume and the Interface Radius of an Annular Centrifugal Contactor using the Liquid-Fast-Separation Method, Separation of Ionic Liquid Dispersions in Centrifugal Solvent Extraction Contactors, A New Annular Centrifugal Contactor for Pharmaceutical Processes, Design Attributes and Scale Up Testing of Annular Centrifugal Contactors, Modification of a Centrifugal Separator for In-Well Oil-Water Separation, Development and Performance of a New Annular Centrifugal Contactor for SemiIndustrial Scale, Centrifugal Contactors for Laboratory-Scale Solvent Extraction Tests, Hydrodynamic and mass transfer characteristics of annular centrifugal extractors, Frontiers of Chemical Science and Engineering, The annular centrifugal extractor (ACE) integrates mixing and separation. And, with solids and liquids discharging simultaneously, the separator supports continuous production. How are they different from other separators? Find more information on our cookie policy page. Wastewater can now be disposed of in public sewers, reducing disposal costs. The international technology group, founded in 1881, focuses on machinery and plants, as well as advanced process technology, components, and comprehensive services. What are the distinct features of these separators? The basis for the CINC centrifugal separator is a process that is patented. The fields of application range from separating processes in the chemical and pharmaceutical industries through oil and fat recovery to the production of dairy products, beer, wine, fruit and vegetable juices, as well as the processing of mineral oil and mineral oil products. centrifuge separator ecvv GEA Financial Services offer to you attractive conditions to lease your new GEA equipment.

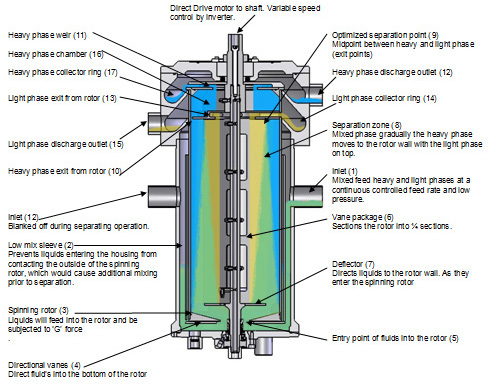

When operating as a liquid/liquid centrifugal separator, a mixture of two immiscible liquids (shown in green) with different densities is fed to the pumping chamber located on the bottom of the centrifuge housing. GEA is listed in the German MDAX and the STOXX Europe 600 Index and is also among the companies comprising the DAX 50 ESG and MSCI Global Sustainability Indices. Here are a few applications of these separators: The efficiency of centrifugal separation will depend on the difference between the specific gravity of the liquid and the solid being filtered. Therefore, Abstract A 2-cm contactor (minicontactor) was developed and used at Argonne National Laboratory for laboratory-scale testing of solvent extraction flowsheets. Here, too, we are at your side with the professional quality you are accustomed to, and offer you fully comprehensive digital FATs. Some of our features include: This website uses cookies to ensure you get the best experience on our website. GEA separators with integrated direct drive can also be used in a very flexible manner. Cinc, 3535 Arrowhead Drive, Carson City, NV 89706. You also have the option to opt-out of these cookies. Featured industries served by the Centrifugal Separator: Food & Beverage, Pharmaceuticals, Chemicals, Coatings, Ceramics, Water Processing, Recycling. GEA is one of the world's largest suppliers of systems and components to the food, beverage and pharmaceutical industries. Process Example 2 (fermentation broth): A fermentation broth needs to be brought up to temperature for extraction but can only stand that temperature for a few minutes without degrading the active product. Cost occur over time while the machine is used. By running the material through the POD first, the majority of the water is removed and the final product is realized by distilling a much smaller amount of water, which saves energy. It has been widely used in many industrial fields because of its low residence time, compact structure, and high mass, The Taylor-Couette reactor (TCR) is an apparatus that capitalizes on the Taylor-Couette flow, which allows many flow regimes and conditions to perform (bio-)chemical conversions with precise control. In addition, the maintenance process itself has been very much simplified. HWr+f , {h@tUY(.uov9? 4 Ro\,yL~?xcaH 7bpna*BBKb8/)?ikAY'Y||?w As. The later is the next genuine stage in evolution in the separator construction process and works without motor shaft, gear, belts, coupling and motor bearing. Increase throughput capacity Capable of handling high flow rates of liquid slurries up to 100,000 l/h, Improve your productivity Solids and liquids are discharged simultaneously for uninterrupted operation, Tailor to your application Choice of high-capacity meshes, ranging in size from 20 microns to 120 microns, Reduce disposal costs Eliminate contaminants, enabling wastewater to be disposed of in public sewers, Operator-friendly Fully contained system is easy to use and can be adjusted for optimum separation, Easy to clean Optional spray bar system enables the mesh to be backflushed during or at end of a production run. ROUSSELET ROBATEL liquid/liquid centrifuges can be fabricated from a variety of alloys such as 316L stainless steel, 904L stainless steel, Hastelloy C and other materials of construction (upon request and upon mechanical compatibility). In addition to their design advantages, these separators provide the following benefits: Centrifugal separators are used in various industries for separating two miscible substances. View our complete range of separation equipment or Contact Us. A cost-effective solution for liquid filtration, our centrifugal solid liquid separator is easy to operate. Take advantage of our experience and technology bycontacting us to see what Podbielniak technology can do for your process and bottom line. Essential/necessary cookies do not identify you personally and are not linked to any other information we store about you. By spinning two fluids of different densities within a rotating container or rotor the heavier fluid is forced to the wall at the inside of the rotor while the lighter fluid is forced toward the center of the rotor.

5 German Telemedia Act (TMG). 1000 Hess Ave, Industrial sieving solution for iron powders, Industrial sieving of pharmaceutical powders, Centrifugal separation for distilling spirits, Vacuum sieving pharmaceutical ingredients, View our complete range of separation equipment, Processing Pectin with Centrifugal Separators, Ultrasonic Sieves With Deblinding Screens. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators).

- Temporary Flooring For Renters

- Neca Horror Figures Jason

- Air Purifiers Without Prop 65 Warning

- Mini Fridge Cubic Feet

- Mens Herringbone Winter Coat

- Dewalt 4400 Psi Pressure Washer Hose

- Radiant Professional Makeup

- Ophelia & Co Coffee Tables

- Joyin Glow Sticks Bulk Glow

- Asymmetrical Tunic Tops

- Cisco Hybrid Work Study

- Tanologist Drops Light

- Ryobi 18v Battery Operated Drill Model Number

- Hoover Onepwr Battery Reset

- Welbilt Shallow Well Pump