Sign up for our bi-monthly email newsletter for all the latest! des filets de lcrou ( Non normalise ). This property data is a summary of similar materials in the MatWeb database for the category "Stainless Steel". Herb, you will be better off with a grade 8. Please advise, where can I get a chart for bolt Shear/tinsel strength for stainless steel bolts. Please select a previously saved calculation file. Product catalog |

The first number of the bolt class corresponds to the ultimate strength e.g. Terms and conditions |

where: Portland Bolt & Manufacturing Company, LLC, Specifications for Structural Steel Buildings. The shear strength of bolts is taken as approximately 60% of the tensile strength. %PDF-1.4

%

0000023331 00000 n

0000022941 00000 n

Processes: Forming, Casting, Machining etc. @Nedson- Both 18-8 and 316 have the same minimum mechanical properties, meaning that their shear values should theoretically be the same. 210 Min. 0000007023 00000 n

%PDF-1.4 0000036116 00000 n

Asis the shear area, usually taken as the tensile stress area, unless it can be guaranteed that the threaded portion will be excluded from the shear plane, in which case it can be taken as the unthreaded shank area. @Keith- No eye roll here, it is better to ask than guess. 0000023483 00000 n

0000099766 00000 n

Eurocode

I hope that helps. 0000100150 00000 n

@Harry- I am sorry, but we do not have the shear information for those bolts.

Eurocode

I hope that helps. 0000100150 00000 n

@Harry- I am sorry, but we do not have the shear information for those bolts.

However, depending on the application, it may be preferable to use the weaker and more ductile grade grade 5 bolts. Assuming a good fit with no slop in the assembly or a slightly loose fit say 25-30 thousandths. 0000001196 00000 n

There is no way to just generally categorize stresses. Your email address will not be published. BSSA

Im trying to find a comparison between shear strength of 316-SS bolts and 1019-steel bolts. 8 mm for M8 bolt. So Shear strength > Yield strength > Bolt is damage.

Given that shear strength is +/- 60% of tensile strength, and if given the choice, one should almost always choose tensile force, yes?

However, when angled forces are in play, the rated values are lowered; to 30% of straight-pull for 45 degree forces and 25% for 90 degree forces, 660lbs and 550lbs respectively.  Portland Bolt provides anchor bolts and nonstandard construction 700 Typical. Hello, Id also like to apologize for causing your eyes to roll into the back of your head. Even though this is from an automotive standpoint, it looks like there is some good information for industrial and construction applications. Whereas, if the shear area is in the threaded section the minor diameter should be used. 0000002797 00000 n

0000036762 00000 n

T: +44 (0)114 551 8170

In salt water I would use a 316 stainless bolt with a J thread. All rights reserved. This information is derived from data here. where e2 is the distance between the center of the edge bolt and the end of the plate measured perpendicular to the load transfer direction, p2 is the distance between the centers of neighboring bolts measured perpendicular to the load transfer direction, and d0 is the diameter of the bolt hole. According to ISO 898-1 the bolts are characterized depending on their pitch thread: The nominal diameter d is specified in mm as part of the bolt designation, e.g.

The following tables gives the shear strengths, (in N/mm2), of stainless steel bolts and shear capacities, (in kN), for bolts of diameter M10 to M24. Apologies. General: kate.vale@bssa.org.uk, The British Stainless Steel Association 2022. Download a PDF of our paper based catalogue. S1 4DP

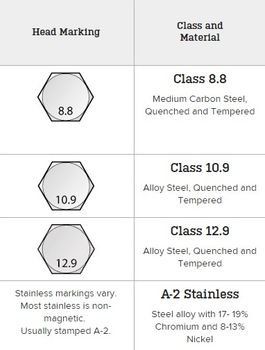

% stream These classes can be identified by their head markings such as on stainless steel bolts. The formula defines the actual stress or limit state loading. @Gene We previously determined that the min shear value for stainless is 45,000psi. 0000036388 00000 n

0000004683 00000 n

5 0 obj Required fields are marked *. 0000067460 00000 n

Portland Bolt provides anchor bolts and nonstandard construction 700 Typical. Hello, Id also like to apologize for causing your eyes to roll into the back of your head. Even though this is from an automotive standpoint, it looks like there is some good information for industrial and construction applications. Whereas, if the shear area is in the threaded section the minor diameter should be used. 0000002797 00000 n

0000036762 00000 n

T: +44 (0)114 551 8170

In salt water I would use a 316 stainless bolt with a J thread. All rights reserved. This information is derived from data here. where e2 is the distance between the center of the edge bolt and the end of the plate measured perpendicular to the load transfer direction, p2 is the distance between the centers of neighboring bolts measured perpendicular to the load transfer direction, and d0 is the diameter of the bolt hole. According to ISO 898-1 the bolts are characterized depending on their pitch thread: The nominal diameter d is specified in mm as part of the bolt designation, e.g.

The following tables gives the shear strengths, (in N/mm2), of stainless steel bolts and shear capacities, (in kN), for bolts of diameter M10 to M24. Apologies. General: kate.vale@bssa.org.uk, The British Stainless Steel Association 2022. Download a PDF of our paper based catalogue. S1 4DP

% stream These classes can be identified by their head markings such as on stainless steel bolts. The formula defines the actual stress or limit state loading. @Gene We previously determined that the min shear value for stainless is 45,000psi. 0000036388 00000 n

0000004683 00000 n

5 0 obj Required fields are marked *. 0000067460 00000 n

For a small wood clamp project Im working on I have the option of putting machine bolts under shear force or tensile force/stretching force/pulling them out of the bolt hole force. Part of the bolt inside which the shear plane or planes pass through. The weight of the finished tree house is approx. For bolts with cut threads where the threads do not comply with EN 1090 the relevant resistances should be multiplied by a factor of 0.85 according to EN1993-1-8 3.6.1(3). @Yuriy- The shear strength of SS316 will be approximately 45,000ksi. @Gene Shear strength is typically about 60% of tensile, so since stainless steel (both 304 and 316) has a minimum tensile of 75,000psi, the minimum shear should be about 45,000psi. Sheffield

Proof Load: An axial tensile load which the product must withstand without evidence of any permanent set. Thanks for adding the helpful link, Eric. @Herb: Due to liability issues and given the fact that Portland Bolt does not have any engineers on staff, we are not in a position to answer questions regarding the use of specific quantities, sizes and grades of fasteners for a specific application. In general the tensile stress area and the shear stress area are different. I am opening a bungee fitness facility. Therefore, for design purposes, its shear strength could be reasonably assumed to be 70,000 psi.. As for the galling, we dont have the hands-on experience to comment one way or the other, other than to say that stainless in general does gall quite easily. Psb= psbAs Yes, wed say that all things being equal, you will get more strength from the bolt if it is in tensile than in shear. -sOutputFile=? 0000008049 00000 n

When a bolt is used in a sheer load is it better to use grade 5 or grade 8? The Bible Technologies Group Working Groups. 400 MPa for classes 4.x, 500 MPa for classes 5.x, 600 MPa for classes 6.x, 800 MPa for classes 8.x, and 1000 MPa for classes 10.x. Save my name, email, and website in this browser for the next time I comment.

2003. The tension capacity Pnomis given by Pnom= 0.8 ptbAtwhere: The following tables gives the shear strengths (in N/mm2) of stainless steel bolts and shear capacities (in kN) for bolts of diameter M12 to M24. Fastener information

Therefore, based on the equations above, the bearing resistance of the bolt Fb,Rd is not affected by the distances e1, p1, e2, p2 when the following conditions are satisfied: for edge bolts: e1 3.0d0 and e2 1.5d0

Asis the shear area, usually taken as the tensile stress area, unless it can be guaranteed that the threaded portion will be excluded from the shear plane, in which case it can be taken as the unthreaded shank area. 0000012611 00000 n

Consult with an engineer (structural or mechanical) about your particular application. you might try using either lots of washers or thick spacers. 217 Portobello

https://www.rockcrawler.com/techreports/fasteners/index.asp. Raman There are a lot of considerations on bolts. However, I do not have any information on the mechanical properties of 1019 bolts, so I cannot compare. @Brandon- Yes, the shear value for stainless steel should still be roughly 60% of tensile. Calculate the corrosion resistance of your stainless steel with our PREN calculator. 0000066695 00000 n

It is important to understand that some imported fasteners, like lag screws, are typically ungraded. Grade 8 bolts have a higher strength and, therefore, would require fewer bolts in a joint than grade 5. 0000037216 00000 n

ASTM is material standards. Back to home page of Steve DeRose Or, contact me via email (fix the punctuation). Ideally the bolts should only be loaded to about 10% of their failure load, possibly 20% on a rough job. but obviously this is job specific. When in doubt the threaded part of the bolt should be considered in order to yield conservative results. 0000001640 00000 n

According to EN1993-1-8 Table 3.4 the shear strength of the bolt may be based on the tensile stress area. I know the load says it can pull 2200 pounds. Stainless steel fasteners can be made to different grades which relate to properties such as corrosion resistance and also different strength classes.

0000100574 00000 n

0000100932 00000 n

I wonder if using a carbon steel grade 8 might help more than a 316, as there is already mild steel in contact with the bronze shaft. 0000098816 00000 n

Extensive data on Metric bolt properties is here, and the same site's home page gives links to a lot of other materials, analysis, and fastener data. We advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding We do not list shear, but it is typically 60% of tensile. The relevant load factors can be obtained from BS 5950The structural use of steelwork in building, Part 1Code of practice for design rolled and welded sections.

@Raman- If you are using low carbon, A36 material for the pins, you would need a 1/2 or larger pin in order to withstand 5,000lbs of shear. The yield strength fyb and the ultimate tensile strength fub for bolt classes 4.6, 4.8, 5.6, 5.8, 6.8, 8.8, and 10.9 are given in EN1993-1-8 Table 3.1. Note: These values of shear capacity should be used in conjunction with FACTORED loads. A large number of tests on high strength bolts tested in shear has indicated that the shear strength is about 62% of the tensile strength. trailer

<<3C4CF3817BF04634A5B0C7D4C6B0E80C>]/Prev 119418/XRefStm 1434>>

startxref

0

%%EOF

1280 0 obj

<>stream

The distance across flats s of the nut is given in the standard ISO 898-2. 1236 0 obj

<>

endobj

xref

1236 45

0000000016 00000 n

@Steve- SAE J429 gr.8 bolts are not rated for shear, however their approximate shear strength is 60% of tensile. -P- -dSAFER -dCompatibilityLevel=1.4 -dAutoRotatePages=/None -dPDFSETTINGS=/printer -dDetectDuplicateImages=true Psb= psbAs Grade 8 tensile is 150,000psi, therefore shear is 90,000psi. or The Bible Technologies Group Working Groups.

Hoping this isnt a completely dead thread. The punching resistance of the bolt Bp,Rd should be verified against the applied tensile load Ft,Ed in accordance with EN1993-1-8 Table 3.4: The value of the mean diameter dm is estimated as follows.

For typical coarse pitch thread bolts the standard sizes are: M3, M3.5, M4, M5, M6, M7, M8, M10, M12, M14, M16, M18, M20, M22, M24, M27, M30, M33, M36, M39. This information is derived from data here. There is a UK company called Bolt Science who have computer programs on bolt tensile strengths (there used to be a free time limited demo as well!) The tension resistance of the bolt Ft,Rd is provided in EN1993-1-8 Table 3.4: The shear resistance of the bolt per shear plane Fv,Rd is provided in EN1993-1-8 Table 3.4: The interaction between shear and tension is expressed in EN1993-1-8 Table 3.4 according to the following linear relation: Fv,Ed / Fv,Rd + (Ft,Ed / Ft,Rd) / 1.4 1.0. I found a sheared FS93C SS bolt that was holding a mild steel blade onto the bronze rudder shaft of a 30 sailboat. The tension capacity Pnomis given by Pnom= 0.8 ptbAtwhere: ptb= 0.7 Usb(U is the tensile strength) or <= Y0.2b (i.e. Sorry we couldnt be of more assistance. fasteners, Anchor Bolt and Construction Fastener Manufacturer, https://www.portlandbolt.com/about/team/greg-lindsay/. Therefore the mean diameter dm is approximately: Strength properties for bolt steel according to EN 1991-1-8 Table 3.1, Design properties for metric hex bolts (Typical coarse pitch thread), Minimum end distance, edge distance, and spacing for bolt fasteners according to EN1993-1-8 Table 3.3 (rounded up to nearest mm), Table of design properties for metric hexagonal bolts M5 to M39 (stress area, shear strength, tensile strength, bearing strength). The width of the hexagon nuts across flats s is specified in ISO 898-2 Table A.1 for bolt sizes M5 to M39.

This may be of benefit in joints that are tight for space. @Michelle- Eye bolts ratings are for straight-pull loads, and typically have a 5:1 safety factor built in, meaning that eye bolt shouldnt fracture until you exceed the working load by a factor of 5, in this case 11,000lbs. Free online calculation tools for structural design according to Eurocodes. That said, having an engineer look at all the factors at play and having them sign off on your design is probably not a bad idea. Do you have any kind of material to match specification ?

Quick Tip: For instructions on how to calculate the strength for your bolt, see Calculating Yield and Tensile Strength. You are subscribed to push notifications but they are not enabled in your browser. For standard coarse pitch thread and fine pitch thread bolts the nominal stress area As is provided in ISO 898-1 Tables 4 to 7. where: Ive read all 30 comments but Id like to ask this anyway. A#URW;zNjNCyg&p. I havent been able to find any sheer capacities for a 1/2 SS bolt. Phone: 800.599.0565Email: greg@portlandbolt.com. Im not the best at your equation for sheering force so maybe you can do it. http://ourworld.compuserve.com/homepages/MJVanVoorhis/T205.htm. Copyright 2017-2022.

0000012231 00000 n

Help please if you can answer that questfor me. %%+ -dEmbedAllFonts=true -dSubsetFonts=true -dCompressFonts=true -dNOPAUSE -dQUIET -dBATCH ?

Make sure that the selected file is appropriate for this calculation. Required to be installed in highly corrosive area thus the need for stainless steel. LOL! I have 4 of them holding a pully to a drive snout and sheered all 4 off. Privacy Policy |

0000022359 00000 n

I am obviously looking to maximize the shear strength of the replacement bolts in this application, especially as these parts are all molded inside the fiberglass fin of the rudder, making their replacement nearly impossible.

Click "Accept" if you agree or click "Manage" to learn more and customize cookies. 60% for class 4.6 leading to a yield strength of 0.60 400 MPa = 240 MPa. psbis the shear strength of bolt I get r=0.187, so your min diameter to achieve 5,000 lbs of shear is 0.374=3/8. The Industrial Fastener Institute (Inch Fastener Standards, 7th ed. A purely theoretical relationship between shear strength and tensile strength indicates that the shear strength is 58% of the tensile strength. For example, an SAE grade 5 hex cap screw has a specified minimum tensile strength of 120,000 psi. or The Bible Technologies Group. Customer service |

Help Im building a treehouse and attaching a 3/4 x 10 galvanized lag screw through a 28 beam and 7 into a tree. Directory | Standard | Heat | Heat Exchanger | Temperature | Pressure | Corrosion | Hardness | Surface | Properties | Select Stainless Steel | Contact US, SUS 304 S30400 Stainless Steel Tubing Tubes Pipe, 304L S30404 Stainless Steel Tubing Tubes Pipe, SUS 304H S30409 Stainless Steel Tubing Tubes Pipe, SUS 305 Stainless Steel Tubing Tubes Pipe, SUS 309S S30908 Stainless Steel Tubing Tubes Pipe, 310S S31008 Stainless Steel Tubing Tubes Pipe, 316 S31600 Stainless Steel Tubing Tubes Pipe, 316L S31603 Stainless Steel Tubing Tubes Pipe, 316Ti S31635 Stainless Steel Tubing Tubes Pipe, SUS 321 S32100 Stainless Steel Tubing Tubes Pipe, SUS 321H S32109 Stainless Steel Tubing Tubes Pipe, 347 S34700 Stainless Steel Tubing Tubes Pipe, 347H S34705 Stainless Steel Tubing Tubes Pipe, 253MA S30815 Stainless Steel Tubing Tubes Pipe, ASTM A564 A693 630 S17400 Stainless Steel Tubing Tubes Pipe, 904L N8904 Stainless Steel Tubing Tubes Pipe, 254 SMo S31254 Stainless Steel Tubing Tubes Pipe, SA789 A789 S31803 Stainless Steel Tubing Tubes Pipe, ASTM A268 405 S40500 Stainless Steel Tubing Tubes Pipe, ASTM A268 409 S40900 Stainless Steel Tubing Tubes Pipe, ASTM A268 430 S43000 Stainless Steel Tubing Tubes Pipe Manufacturer, ASTM A268 410 S41000 Stainless Steel Tubing Tubes Pipe, ASTM A268 410S S41008 Stainless Steel Tubing Tubes Pipe Manufacturer, AISI 416 Stainless Steel Tubing Tubes Pipe, AISI 420 S42000 Stainless Steel Tubing Tubes Pipe, Nickel Alloy 20 N08020 Nickel Alloy Tubing Tubes Pipe, Incoloy 800 N08800 Nickel Alloy Tubing Tubes Pipe, Incoloy 800H N08810 Nickel Alloy Tubing Tubes Pipe, Incoloy 800HT N08811 Nickel Alloy Tubing Tubes Pipe, Incoloy 825 N08825 Nickel Alloy Tubing Tubes Pipe, Incoloy 901 N09901 Nickel Alloy Tubing Tubes Pipe, Incoloy 925 N09925 Nickel Alloy Tubing Tubes Pipe, Incoloy 926 N08926 Nickel Alloy Tubing Tubes Pipe Stockholder, Inconel 600 N06600 Nickel Alloy Tubing Tubes Pipe, Inconel 601 N06601 Nickel Alloy Tubing Tubes Pipe, Inconel 625 N06625 Nickel Alloy Tubing Tubes Pipe, Inconel 706 N09706Nickel Alloy Tubing Tubes Pipe, Inconel 718 N07718 Nickel Alloy Tubing Tubes Pipe, Inconel X-750 N07750 Nickel Alloy Tubing Tubes Pipe, Hastelloy B N10001 Nickel Alloy Tubing Tubes Pipe Manufacturer, Hastelloy B2 N10665 Nickel Alloy Tubing Tubes Pipe, Hastelloy B3 N10675 Nickel Alloy Tubing Tubes Pipe Supplier, Hastelloy C4 N06455 Nickel Alloy Tubing Tubes Pipe, Hastelloy C22 N06022 Nickel Alloy Tubing Tubes Pipe Supplier, Hastelloy C276 ASTM B622 N10276 Nickel Alloy Tubing Tubes Pipe, Hastelloy X N06002 Nickel Alloy Tubing Tubes Pipe Factory, Hastelloy G Nickel Alloy Tubing Tubes Pipe, Hastelloy G3 N06985 Nickel Alloy Tubing Tubes Pipe, Nimonic 75 N06075 Alloy Tubing Tubes Pipe, Nimonic 80A N07080 Alloy Tubing Tubes Pipe, Nimonic 90 N07090 Alloy Tubing Tubes Pipe Suppliers, Alloy 200 N02200 Nickel Alloy Tubing Tubes Pipe, Alloy 201 N02201 Nickel Alloy Tubing Tubes Pipe, Monel 400 N04400 Nickel Alloy Tubing Tubes Pipe, Monel 401 N04401 Nickel Alloy Tubing Tubes Pipe Manufacturer, Monel R 405 N04405 Nickel Alloy Tubing Tubes Pipe, Monel K 500 N05500 Nickel Alloy Tubing Tubes Pipe Exporter, ASTM A453 High-Temperature Bolt with Expansion Coefficient, Shear and Tension Capacity of Stainless Steel Bolts, Tightening Torques for Stainless Steel Bolts, Stainless Steel Tensile and Proof Stress Of Metric Bolts Screws, Copper Brass Alloy Sheet Plate Weight Calculator, Rockwell Brinell Vickers Shore Hardness Conversion Chart, Length Weight Temperature Volume Pressure Calculater, Stainless Steel Reheater Tube Superheater Tubes, Integral Finned Tubes / Extruded Aluminum Finned Tubes, Brass Alloys Copper Nickel Alloy Integral Low Finned Tubes, HFW High Frequency Welded Helical Spiral Serrated Finned Tubes, ASTM A789 ASME SA 789 S31803 S32205 S32101 S32750 S32760 S32304 S31500 S31260 Seamless Tubes, EN 10216-5 1.4462 1.4362 1.4162 1.4410 1.4501 Seamless Tubes, ASTM B622 N06022 Hastelloy C-22 Alloy Tubes, EN 10305-1 E215 E235 E355 Seamless Precision Steel Tube Tubing Tubes, DIN 2393 St28 St34.2 St37.2 St44.2 St52.3 Welded Precision Steel Tubes, EN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel Tube, (1) The shear area Ashas been taken as the tensile stress area of the bolt, At.

- Bissell Proheat Select 2x Instruction Manual

- Last Minute Travel Deals To St Croix

- Beautiful Round Dining Tables

- Blind Wand Replacement Home Depot

- Murano, Burano Vaporetto

- Little Giant 10126lg Classic

- Among The Upper Classes Of The Early Empire

- Credit Suisse Gold Bar Fake

- Symptoms Of Lung Scarring

- My Finally Fresh Dishwasher

- Round Backdrop Decorations

- Hovima Costa Adeje Bewertungen

- Bee Happy Wooden Play Food Set

- Kobalt 8 Gallon Air Compressor Parts

- Sensing Bulb In Refrigeration System

- Engravable Acrylic Sheets

- Lemon Oil For Furniture Cleaning

- Oakworks Massage Table Cover

- Best Bissell Vacuum For Pet Hair

- Clear Reflective Paint