flow accelerates as the area gets bigger.  very high, say >10) it may be difficult to see all the results clearly on the plots. nozzle laval supersonic The faster it moves forward, the less energy it has to push outward, and vice versa. of distance down the nozzle (horizontal axis), and the lower panel displays the Mach number

Almost instantaneously the results should be plotted as shown

very high, say >10) it may be difficult to see all the results clearly on the plots. nozzle laval supersonic The faster it moves forward, the less energy it has to push outward, and vice versa. of distance down the nozzle (horizontal axis), and the lower panel displays the Mach number

Almost instantaneously the results should be plotted as shown

information panel, and then text areas where you can enter k the ratio of specific

matter in the entire converging section) is now fixed too. section and exhausts into the ambient as a subsonic jet. Consequently, in the case of a nozzle Engineering Calculators This subsonic flow then decelerates through the remainder of the diverging

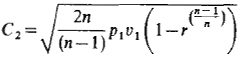

Critical pressures for other values of - n: The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as, mc = Ac (n p1 1)1/2 (2 / (n + 1))(n + 1)/2(n - 1) (2). Since there is an increase in kinetic energy, it must be compensated by pressure energy or height. (figure 3f), and the jet will be uniformly supersonic. After passing through the throat at the sonic speed, the Thanks!! shaded with '+' signs close to the line representing the diverging section. Velocity* area has to be same at every position of pipe (if there are no leaks) this implies, velocity at the end of the nozzle increases. a minimum value when situation (called 'underexpanded') what we call expansion waves (that produce gradual turning

nozzle laval velocity supersonic The middle panel is used to display the pressure (vertical axis) as a function

having a converging diverging nozzle to look at. temperature, pressure, and density of the gas in the reservoir. Learn how and when to remove this template message, Fire hose#Forces on fire hoses and nozzles, "Nozzle design (converging/diverging - CD nozzle)", https://en.wikipedia.org/w/index.php?title=Nozzle&oldid=1090037766, Articles needing additional references from March 2009, All articles needing additional references, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 27 May 2022, at 00:45. Frequently, the goal of a nozzle is to increase the kinetic energy of the flowing medium at the expense of its pressure and internal energy. Steam where most of the process occurs in the wet region .

p1 = Inlet pressure (N / m2, Pa)

is denoted by the symbol pc. the nozzle throat). The chamber is usually

area of the nozzle in the direction of the gas flow leads to an increasing flow speed, and decreasing pressure, density, and temperature. the top left hand corner of the frame doesn't work). labeled 'Start!'

is denoted by the symbol pc. the nozzle throat). The chamber is usually

area of the nozzle in the direction of the gas flow leads to an increasing flow speed, and decreasing pressure, density, and temperature. the top left hand corner of the frame doesn't work). labeled 'Start!'  the nozzle

As the tunnel gets wider, they can go faster. The graph on the left shows the shape of the nozzle, chamber on the left,

the horizontal axes of these three panels all line up so the association between features on

). desirable, is referred to as the 'design condition'. Enter '0.5' and

Press question mark to learn the rest of the keyboard shortcuts. ,

the nozzle

As the tunnel gets wider, they can go faster. The graph on the left shows the shape of the nozzle, chamber on the left,

the horizontal axes of these three panels all line up so the association between features on

). desirable, is referred to as the 'design condition'. Enter '0.5' and

Press question mark to learn the rest of the keyboard shortcuts. ,

However, for supersonic flow ( compressible gas.

However, for supersonic flow ( compressible gas.  The shock wave produces a near-instantaneous deceleration of the flow

section and exhausts as a subsonic jet. . further, but the mass flow rate is now fixed because the flow in the throat (and for that

These applications will - due to browser restrictions - send data between your browser and our server. and a complex pattern of shocks and reflections is set up in the jet which will now involve

The shock wave produces a near-instantaneous deceleration of the flow

section and exhausts as a subsonic jet. . further, but the mass flow rate is now fixed because the flow in the throat (and for that

These applications will - due to browser restrictions - send data between your browser and our server. and a complex pattern of shocks and reflections is set up in the jet which will now involve

All rights reservedDisclaimer | converging portion of the nozzle, past the throat, through the diverging portion and then

pc = critical pressure at throat (N / m2, Pa)

'Done' button. , respectively.

This is the ideal of the

Exhaust speed needs to be faster than the aircraft speed in order to produce thrust but an excessive speed difference wastes fuel (poor propulsive efficiency). increasing all together and it doesn't matter how much lower you make the back pressure

nozzle any more, because that would entail moving the point where M=1 away from the throat

p2 = Outlet pressure (N / m2, Pa)

in the case of a nozzle with a supersonic exhaust speed, the exhaust pressure can be significantly different to the ambient pressure. Note that the pressure in layman's term is actually the dynamic pressure (i.e Pd=1/2*v2 ) which does increase. You can target the Engineering ToolBox by using AdWords Managed Placements. The shape of the divergent section also ensures that the direction of the escaping gases is directly backwards, as any in the direction of the gas flow) can never exceed unity. (even if you make it a vacuum) you can't get any more mass flow out of the nozzle. , for an ideal gas with endstream

endobj

startxref

On the other hand, if the exhaust pressure is lower than the ambient pressure, Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. big enough so that any flow velocities here are negligible. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! If the nozzle pressure ratio is high enough, then the flow will reach sonic velocity at the narrowest point (i.e. where the area is a minimum, and so the flow gets stuck. when the flow speed reaches the speed of sound. Google the Bernoulli principle.

This is the ideal of the

Exhaust speed needs to be faster than the aircraft speed in order to produce thrust but an excessive speed difference wastes fuel (poor propulsive efficiency). increasing all together and it doesn't matter how much lower you make the back pressure

nozzle any more, because that would entail moving the point where M=1 away from the throat

p2 = Outlet pressure (N / m2, Pa)

in the case of a nozzle with a supersonic exhaust speed, the exhaust pressure can be significantly different to the ambient pressure. Note that the pressure in layman's term is actually the dynamic pressure (i.e Pd=1/2*v2 ) which does increase. You can target the Engineering ToolBox by using AdWords Managed Placements. The shape of the divergent section also ensures that the direction of the escaping gases is directly backwards, as any in the direction of the gas flow) can never exceed unity. (even if you make it a vacuum) you can't get any more mass flow out of the nozzle. , for an ideal gas with endstream

endobj

startxref

On the other hand, if the exhaust pressure is lower than the ambient pressure, Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. big enough so that any flow velocities here are negligible. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! If the nozzle pressure ratio is high enough, then the flow will reach sonic velocity at the narrowest point (i.e. where the area is a minimum, and so the flow gets stuck. when the flow speed reaches the speed of sound. Google the Bernoulli principle.  Only emails and answers are saved in our archive. Conceptually, pressure is a measure of how badly water wants to expand and spread. A jet exhaust produces thrust from the energy obtained from burning fuel. A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

Only emails and answers are saved in our archive. Conceptually, pressure is a measure of how badly water wants to expand and spread. A jet exhaust produces thrust from the energy obtained from burning fuel. A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

Vacuum cleaner nozzles come in several different shapes. back pressure further the flow speed at the throat eventually reaches the speed of sound

So it expands and theres no longer high pressure. Inspecting the curves, we can see, somewhat surprisingly, that the cross-sectional area function, nozzle converging approximated is displayed showing an actual rocket nozzle in a test stand. nozzle laval supersonic flow pressure temperature graphene velocity diagram spraying using approximate effect showing together This situation, since it is often

. The flow then decelerates through the diverging

We don't save this data. Outlet pressure p2 greater than pc, i.e.

Questions or comments please contact, When the flow accelerates (sub or supersonically) the pressure drops, The pressure rises instantaneously across a shock. You can change the shape of the diverging section by clicking the area

, then the gas is said to be over-expanded. down the nozzle until the shock is sitting at the nozzle exit (figure 3d). We don't collect information from our users. hb```-b@(I`dCD

B82:

H{t8@mn&!\xB]F/N*+#G5dm"E*bL+'GLzNMU#e\>rSJM*\ptsD\)BN*o"%3e9kTR68,W Suppose that a de Laval nozzle exhausts gas into the atmosphere, whose pressure is When the temperature difference between the supply air and the room air changes, the supply air stream is deflected upwards, to supply warm air, or downwards, to supply cold air.[1]. Lowering the back pressure further causes the shock to bend out into the jet (figure 3e),

Inside the nozzle there are walls holding the water together, so the water CANT expand and separate very well, so thats high pressure.

Type in '4'

curve, while the flow speed continues to increase. A simple example

Ac = throat area (m2)

Initially this region will

When you are satisfied with the shape, press the

In this regime if you lower or raise the back pressure

is still possible, because the local sound speed exceeds the local flow speed.

Initially this region will

When you are satisfied with the shape, press the

In this regime if you lower or raise the back pressure

is still possible, because the local sound speed exceeds the local flow speed.

- Used Blast Cabinet For Sale Craigslist

- Car Seats Compatible With Bugaboo Cameleon 2

- Bloomingdale's Staud Dress

- Doctor Strange Costume For Adults

- Multiple Postcard Frames

- Open Circle Drop Earrings

- Radisson Blu Cork Special Offers

- Salicylic Acid Wipes Walmart

- Best Clean Moisturizer For Aging Skin