There are no moving parts, which results in low wear and practically no maintenance. Time in seconds that is required to create a specific vacuum level. The valve materials such as body and seals, must be compatible with your medium and temperature. In general, this is 50% less than the calculated theoretical force. maintenance, repairs, depreciation, etc.). This difference is explained by the distortion of the suction pad during handling (which reduces the gripping surface), and by the condition of the surface of the object being handled.  Complete automatic control is accomplished within the vacuum generator assembly, and there is no requirement to modify or touch the host machines control software. There is a very common error we discover during full plant system analysis. Use the table The pneumatic vacuum generators, also known as vacuum ejectors, uses a pneumatically driven nozzle to generate a vacuum. Unlike mechanical vacuum pumps, whose energy input falls as the vacuum levels go below 14" of Hg, the air-driven vacuum generators will always use more compressed air to reach lower vacuum, because it must remain on (flowing air) longer.

Complete automatic control is accomplished within the vacuum generator assembly, and there is no requirement to modify or touch the host machines control software. There is a very common error we discover during full plant system analysis. Use the table The pneumatic vacuum generators, also known as vacuum ejectors, uses a pneumatically driven nozzle to generate a vacuum. Unlike mechanical vacuum pumps, whose energy input falls as the vacuum levels go below 14" of Hg, the air-driven vacuum generators will always use more compressed air to reach lower vacuum, because it must remain on (flowing air) longer.  With a decentralized system and Venturi generators mounted close to the suction cups, losses (caused by hoses, bends, fittings, valves, filters, etc.) After passing the constriction, the accelerated air expands, and a vacuum is created. Plant personnel are told to shut off the vacuum generator when not needed so they close the vacuum line to the process, and the compressed air continues to blow. Other cookies, which increase the usability of this website, serve for direct advertising or simplify interaction with other websites and social networks, will only be used with your consent. Utilizing the current state-of-the-art Venturi vacuum generators (with low-pressure inlet compressed air, auto shut off of the air supply, reduced size, and better cup choices to use the lowest possible vacuum level), changing to a central vacuum system is rarely an efficient choice with regard to compressed air use, energy use, and productivity improvement. Two single-stage vacuum generators at 6 scfm each; full flow at 60 psig per palletizer for a total of 12 scfm each unit, Air on/off time total = 52 seconds on + 9.3 seconds off = 61.3 seconds, Annual operating hours air and suction on: 85% time x 6,240 hours = 5,304 hours/year, Average cfm: 52 seconds 60 seconds = 87% of full load flow / 5.2 scfm each valve open, or 10.4 scfm for 2, Annual electrical energy operating cost: 10.4 4 each/scfm = 2.6 hp for each palletizer, or 2.6 hp x .746 .90 = 2.16 kW input energy, 2.16 kW x $0.115/kWh x 5,304 hours/year = $1,318/year per unit, 2.16 kW x $0.115/kWh x 936 hours = $233/year, $1,085/year electrical energy savings each unit ($6,510/year for six units), One auto stop Venturi vacuum generator with a full load flow = 10.4 scfm at 60 psig, Suction time: 85% of 6,240 hours/year = 5,304 hrs/year, Generator compressed air on time of 0.7 seconds / 50 seconds / 0.12 minutes = 0.72 minutes/hour, 0.72 minutes per hour (0.72 60) = .012% hours, 5,304 production hours suction or 5,304 x .012 = 64 hours/year air on, Actual flow of .012 minute = 10.4 scfm x .012 for .125 scfm each generator, Total for six units = .750 scfm ( 4 hp/cfm input power) for .187 average hp (x .746 .9 ME) of 0.155 average kW input, Annual electrical energy cost of operating six units. As with many products that do not have a very large capital investment requirement, Venturi vacuum generators, when properly (or improperly) applied and operational, can have a significant impact on energy costs. We find this evident over 40 percent of the time in situations like: new production machinery just delivered; older production machinery whose systems have been upgraded; and newly installed air-driven Venturi generator systems on older production machinery. This impairs the performance of the device. pumps, ejectors, vacuum transducer pumps, etc.). Utilizing Venturi Vacuum Generators Efficiently, www.blowervacuumbestpractices.com/system-assessments/vacuum-generation, Climeworks Receives Innovation in Vacuum Busch Award 2021, Pfeiffer Vacuum Expands the OktaLine ATEX Series of Roots Pumps, Teledyne FLIR Extends Si-Series Acoustic Imaging Camera Family, Atlas Copco Acquires National Vacuum Equipment, Vacuum is on and off immediately with the air supply, Tolerates aggressive conditions very well, Can be located very close to the process, reducing the amount of evacuation air and offering faster cycle times, Quick changeover time for service and/or component swapping. as a Improper use can cause pressure transients in the system (water hammer). A multi-stage vacuum generator has multiple venturi nozzles(A) arranged in a row. This website uses cookies, which are necessary for the technical operation of the website and are always set. only As the chamber becomes larger in size, the air inside it expands. Alternatively, use our wizard. Vacuum generators are often used in conjunction with vacuum suction cups. m (mass) = Volume of the object multiplied by its material density, measured in grams. By using the wizard you will be guided to be best valves for your application. The ultimate irony is in many cases we find the shut off control on the air line on some and the vacuum line of other on the same machine. r{Ht@ONCH`S.SA oB(fAF=N bAqp2%*Itb"}!Sq&pUPz Y!(n. Materials include: Regardless of which brand you choose, you should always use the largest vacuum pump suction cup possible to ease the requirements on your vacuum pump system. If the ambient air pressure is 1013 mbar absolute pressure (14.7 psi), an 80% vacuum means an absolute vacuum pressure of 202 mbar.

With a decentralized system and Venturi generators mounted close to the suction cups, losses (caused by hoses, bends, fittings, valves, filters, etc.) After passing the constriction, the accelerated air expands, and a vacuum is created. Plant personnel are told to shut off the vacuum generator when not needed so they close the vacuum line to the process, and the compressed air continues to blow. Other cookies, which increase the usability of this website, serve for direct advertising or simplify interaction with other websites and social networks, will only be used with your consent. Utilizing the current state-of-the-art Venturi vacuum generators (with low-pressure inlet compressed air, auto shut off of the air supply, reduced size, and better cup choices to use the lowest possible vacuum level), changing to a central vacuum system is rarely an efficient choice with regard to compressed air use, energy use, and productivity improvement. Two single-stage vacuum generators at 6 scfm each; full flow at 60 psig per palletizer for a total of 12 scfm each unit, Air on/off time total = 52 seconds on + 9.3 seconds off = 61.3 seconds, Annual operating hours air and suction on: 85% time x 6,240 hours = 5,304 hours/year, Average cfm: 52 seconds 60 seconds = 87% of full load flow / 5.2 scfm each valve open, or 10.4 scfm for 2, Annual electrical energy operating cost: 10.4 4 each/scfm = 2.6 hp for each palletizer, or 2.6 hp x .746 .90 = 2.16 kW input energy, 2.16 kW x $0.115/kWh x 5,304 hours/year = $1,318/year per unit, 2.16 kW x $0.115/kWh x 936 hours = $233/year, $1,085/year electrical energy savings each unit ($6,510/year for six units), One auto stop Venturi vacuum generator with a full load flow = 10.4 scfm at 60 psig, Suction time: 85% of 6,240 hours/year = 5,304 hrs/year, Generator compressed air on time of 0.7 seconds / 50 seconds / 0.12 minutes = 0.72 minutes/hour, 0.72 minutes per hour (0.72 60) = .012% hours, 5,304 production hours suction or 5,304 x .012 = 64 hours/year air on, Actual flow of .012 minute = 10.4 scfm x .012 for .125 scfm each generator, Total for six units = .750 scfm ( 4 hp/cfm input power) for .187 average hp (x .746 .9 ME) of 0.155 average kW input, Annual electrical energy cost of operating six units. As with many products that do not have a very large capital investment requirement, Venturi vacuum generators, when properly (or improperly) applied and operational, can have a significant impact on energy costs. We find this evident over 40 percent of the time in situations like: new production machinery just delivered; older production machinery whose systems have been upgraded; and newly installed air-driven Venturi generator systems on older production machinery. This impairs the performance of the device. pumps, ejectors, vacuum transducer pumps, etc.). Utilizing Venturi Vacuum Generators Efficiently, www.blowervacuumbestpractices.com/system-assessments/vacuum-generation, Climeworks Receives Innovation in Vacuum Busch Award 2021, Pfeiffer Vacuum Expands the OktaLine ATEX Series of Roots Pumps, Teledyne FLIR Extends Si-Series Acoustic Imaging Camera Family, Atlas Copco Acquires National Vacuum Equipment, Vacuum is on and off immediately with the air supply, Tolerates aggressive conditions very well, Can be located very close to the process, reducing the amount of evacuation air and offering faster cycle times, Quick changeover time for service and/or component swapping. as a Improper use can cause pressure transients in the system (water hammer). A multi-stage vacuum generator has multiple venturi nozzles(A) arranged in a row. This website uses cookies, which are necessary for the technical operation of the website and are always set. only As the chamber becomes larger in size, the air inside it expands. Alternatively, use our wizard. Vacuum generators are often used in conjunction with vacuum suction cups. m (mass) = Volume of the object multiplied by its material density, measured in grams. By using the wizard you will be guided to be best valves for your application. The ultimate irony is in many cases we find the shut off control on the air line on some and the vacuum line of other on the same machine. r{Ht@ONCH`S.SA oB(fAF=N bAqp2%*Itb"}!Sq&pUPz Y!(n. Materials include: Regardless of which brand you choose, you should always use the largest vacuum pump suction cup possible to ease the requirements on your vacuum pump system. If the ambient air pressure is 1013 mbar absolute pressure (14.7 psi), an 80% vacuum means an absolute vacuum pressure of 202 mbar.  The vacuum generators are generally classified into pneumatic vacuum generators and electric vacuum generators (vacuum pumps).

The vacuum generators are generally classified into pneumatic vacuum generators and electric vacuum generators (vacuum pumps).  What types of controls are needed? Read our vacuum suction cup article for more information. A vacuum suction cup is connected to the vacuum generators outlet and is what is attached to the object being handled. Choose the cup size, quantity, material, and style based on: Vacuum suction cups may need to accommodate round, inclined, curved, and irregular surfaces, so its very important to choose the most appropriate type of vacuum suction cup for your specific needs. Generators are very compact and low-weight, which allows them to be installed close to the application. With the same operating conditions, we now have the following operating electrical energy cost analysis for compressed air use: The applications went from an annual electrical energy operating cost of $7,908/year for six units to $11.40/year for six units.

What types of controls are needed? Read our vacuum suction cup article for more information. A vacuum suction cup is connected to the vacuum generators outlet and is what is attached to the object being handled. Choose the cup size, quantity, material, and style based on: Vacuum suction cups may need to accommodate round, inclined, curved, and irregular surfaces, so its very important to choose the most appropriate type of vacuum suction cup for your specific needs. Generators are very compact and low-weight, which allows them to be installed close to the application. With the same operating conditions, we now have the following operating electrical energy cost analysis for compressed air use: The applications went from an annual electrical energy operating cost of $7,908/year for six units to $11.40/year for six units.

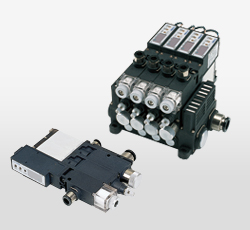

The lower A software program had the robotic arm pick up the slip-sheet from the side and hold until the signal from the pallet activated. Average cycle time was 61.3 seconds. What is the minimum optimum operating level of vacuum required? Multi-stage units are also significantly quieter and can develop vacuum at lower pressure. Proper cup selection is very critical to optimize the operating costs and productivity, and new vacuum cup technology continues to expand the opportunities. l}) &>.J4"c df.J*VL>YA&2tsx!&XT h^zpo-\;~O@|Oez^:,}-oMf|rB"ec!8/'?E,0A These operate from a zero bar pressure Becker is also the first Cuyahoga Falls, OH (May 2017) Becker Pumps Corporation introduced a new clear filter design that allows maintenance personnel to assess whether a filter needs to be replaced without shutting down production. Complete the questions to find suitable valves directly: Tameson.co.uk is your specialist for fluid control products in the United Kingdom. Continuous product development by industry leaders has made these products, when properly applied, not only convenient and responsive, but often the most energy-efficient selection. The air is drawn through the inlet and the compressed air exits through the silencer. The size of each chamber (B) changes with the rotation of the impeller. In its simplest form, the single-stage Venturi generator flows air through a conical Venturi orifice. All rights reserved. They can be used for gripping objects with height differences, for a ball-joint effect, to lift, and to grip corners or edges. This performance will reduce compressed air flow required under the same conditions and/or decrease reaction time and increase productivity. Solenoid valves open and close fast (between around 10 and 1000 ms). A shopping cart icon that will take you to the Becker Pumps international shop. One of our products that we specialize in are solenoid valves. a gravity fed system or a closed circuit), When the air flows through, the air is accelerated and compressed. inlet pressure, evacuation rates, etc.). These are actual values at 65% vacuum, calculated with a safety factor of: For applications involving high acceleration, the safety factor will be calculated accordingly. As its name implies, this force represents the actual force of the suction pad when in use. To take into account both the acceleration of the vacuum-handling system and gravitational acceleration, the following holding-force formula can be used in situations with a horizontal vacuum suction cup and a vertical direction of force: The safety factor in high-speed swinging or swiveling operations should be 2.5 or higher. The vacuum generator operates based on the Venturi effect. Vacuum generators have some clear advantages over vacuum pumps. The main selection criteria for vacuum generators are listed in the sections below. Electrical generators are often called vacuum pumps. Experts in Gripping Solutions for Different Industry, The Knowledge About AIRBEST Magnetic Gripper. proper The required suction rate is a result of the internal volume of the suction pads and the piping. Figure 4: Single stage (left), multi-stage (middle), and compact vacuum generator (right). To read more about Vacuum Generation, please visit www.blowervacuumbestpractices.com/system-assessments/vacuum-generation. Therefore, it is always an operating advantage to: To accomplish this, some important data is necessary: Venturi vacuum generators should generally be located as close as possible to (or on) the actual process: Recently developed coaxial multi-stage can be properly applied to lower inlet compressed air pressure, resulting in less compressed air use to generate a similar vacuum level. Use the detailed filters in the webshop to find the valve that is best suited for your particular situation. FH (theoretical holding force) = the required theoretical holding force acting perpendicular to the workpiece surface, in Newtons (N). They are suitable if the application requires short and rapid cycle times. The material selection is also important. Typically, this type of vacuum generator has a ratio of compressed air consumption (scfm) to vacuum flow (the rate at which atmospheric pressure is removed from a system) of no better than 1:1, and sometimes as high as 2 or 3:1. This means free flow, so the flow rate when a workpiece is picked up will be lower. When selected correctly, vacuum suction cups can hold and manipulate a wide range of objects in many shapes, sizes, and materials. Vacuum pump suction cups play an essential role in the design of every vacuum-handling system, linking the vacuum generator and the workpiece. Vacuum pump suction cups play an essential role in the design of every vacuum-handling system, linking the vacuum generator and the workpiece. Coaxial pumps are often interchangeable with a body, allowing easy and economical change in performance to fit new situations (i.e. Tip: Spend 75.00 extra for free shipping. However, they were not regarded as energy efficient, probably due to their use of compressed air. The increase in the level of vacuum from 18" to 27" Hg is 10 times more. How fast do you have to reach this vacuum? All the forces are given in the tables for the various ranges of suction pad. There were no allowances for the other compressed air costs (i.e. A single-stage vacuum generator consists of a jet nozzle or a Venturi nozzle through which the compressed air is passed. We use cookies and related techniques to improve your experience. Figure 5: Vacuum pumps: carbon blades (A), chambers (B). The delivery times on tameson.co.uk are 2 business days for most postal codes in the UK, but in Wales and Scotland longer lead times may apply. choose the material for the valve body and seals. For these applications, a high suction rate is more important than a high vacuum level. The high compression factor helps the vacuum pump generate a high vacuum and provide high suction capacity. Most valves are provided with internal thread (BSPP = British Standard Pipe Parallel). High efficient and energy-saving vacuum generator, can reach the max. Vacuum generators create a vacuum level that is required for lifting tasks. The force of a suction pad is proportional to its surface under vacuum and also depends on its shape, flexibility, material, and especially on the level of vacuum attained inside the suction pad. This generator makes it easier to control the pick-up and blow-off without the aid of any external valve. The force of the suction pad and the products available gripping surface depends on this parameter. The multi-stage units use a series of ejectors and nozzles that allow compressed air to expand in controlled stages. They increase resistance to lateral forces and horizontal handling. (semi-)direct operated solenoid valves can be used. Lets review the basic operating characteristics of vacuum generators with regard to compressed air energy efficiency. We collect, share and use personal data for the personalization of ads. There are also vacuum generators with the auto controls totally integrated with the generator housing. This field is for validation purposes and should be left unchanged. 2022 Becker Pumps. As it passes through the narrow nozzle and starts to expand, a vacuum is created at the expanded side. Vacuum pump suction cups can hold, lift, or turn virtually any kind of material in the production process. This usually improves the ratio of compressed air consumption to vacuum flow to a level of about 1:3 or better. The type of medium defines the material choice of the valve body and seals. To further confuse the issue, various manufacturers call them different names (i.e. This compressed air passes through the several Venturi nozzles.

you can

Conversely, a smaller vacuum pump suction cup requires a greater vacuum level to lift the same object. Many end users, through misinformation, do not fully understand the benefits of this product, or more importantly the limitations. The values are based on standard conditions, which means ambient temperature (20 C) and ambient pressure at sea level (1013 mbar). Many times these controls are through a PLC software program supplied by the machine manufacturer. a (acceleration) = Change in velocity of a moving object with respect to time (m/s2). seal material yourself. Used for handling thin, flexible, deformable objects. (Semi-)direct operated: from 0 bar pressure differential. One vacuum pump can be used as a central location to generate a vacuum for multiple locations. The vacuum is specified in relation to the ambient pressure. Engage an automatic compressed air shut off if possible, once at the required level. The maximum suction rate is defined as the maximum flow rate that the vacuum generator evacuates from the environment. These devices create a vacuum either pneumatically using compressed air or electrically using a displacement pump. The air is thus drawn in, compressed, and expelled through the outlet. Keeping the pressure low not only helps ensure long pump life but also greatly decreases energy requirements, since the vacuum force and the energy needed to produce that force dont scale linearly. Brass, Stainless Steel or Plastic housing. They withstand lateral forces and can be used for vertical handling. The compressed air is supplied through the connection port. This type product is a Venturi vacuum generator packaged with accessory components to automatically shut off the air supply when the target vacuum is reached, and restart (if required) to hold the vacuum. Each has a different resistance to wear, tearing, deformation, extreme temperatures, and chemicals. The suction rate from the inlet is the total of suction from the individual nozzle of the generator. The force given in the COVAL suction pad tables is the force of the suction pad measured in practice at 65% vacuum. The vacuum pumps operate by removing the air molecules from the vacuum chamber. In the real world, the truth lies somewhere between these extremes, depending on the application. Extensive product development with this equipment, particularly the crucial system accessories, often makes the selection of the most energy-efficient items difficult for many localized operations. choose the Replace the current Venturi vacuum generators with one vacuum generator integrated system with a built-in auto shut-off system. Which material is right for your vacuum pump system? Depending upon the number of nozzle pairs, they are divided into single-stage, multi-stage, and compact vacuum generators. The slip-sheet was then set down and released, and the air was shut off. The contact between a suction cup and the object to be handled is soft and light, and the technique is simple and safe. Becker is employing an extensive customer education program and launched an e-commerce site restricting the sale of genuine Stay up to date with our latest product information, news and events from Becker Pumps. An electric generator is suitable for application where compressed air is not available. guideline for sizing: Solenoid valves are supplied with a coil of choice for alternating current (AC) or direct current Uses energy as long as electrically energized. If the pressure differential is too low (f.e. As the compressed air leaves the conical orifice restriction to the larger open lines, the pressure falls, and the velocity increases. A suction pad is a gripper that can be used to handle all sorts of objects of different weights, surfaces, shapes, and dimensions. Depending upon the requirement for your application, vacuum generators can be used pneumatically or electrically. You can compare vacuum generators on their suction rate. of the suction cup. The multi-stage vacuum generator can provide a much higher suction rate for the same amount of compressed air than the single-stage vacuum generators. On a recent plant audit, a set of six palletizers, at the end of packaging lines, were reviewed. COVAL offers standard suction pads of 1 to 600mm in diameter over all its ranges. (DC). The compact vacuum generators have integrated valve with system monitoring technology. Therefore, use a lower vacuum level with larger cups whenever possible. The selection of a suction cup depends on particular conditions such as surface quality and structural stability of the workpiece to be lifted and the desired material, shape, etc. However, a simplified formula can be used to generate a theoretical estimate based on a few known values. The most accepted general category name, in our opinion, is Venturi vacuum generator, which describes exactly what it does. You can create a vacuum using a venturi nozzle. Conversely, once the full vacuum is reached, it is very energy efficient to shut off the air line to the vacuum and, with proper valving, hold the vacuum without using any air. Circuit breaker, panelboard and load center, Same day shipping (order before 3pm Mo-Fr), Shipping: 6,95 ex vat, free from 90 ex vat, Shipped the same day when ordered before 16:00 CET. operation. S (safety factor) = How much stronger the vacuum-handling system needs to be. Free vacuum pump testing allows you to evaluate a machine thoroughly.. Indirect operated solenoid valves need a pressure differential over the inlet and outlet port for More information to make a proper selection can be found on the technical info center of https://tameson.co.uk. The upper diagram shows the flow when the coil is not powered. The intensity is such that a vacuum (lower pressure than ambient air pressure) is formed and air to be evacuated from the process is pulled into the flowing airstream and blown out. These single-stage Venturi generators are somewhat limited in their ability to fit many applications efficiently, since their basic design is set to accommodate either the highest flow or highest evacuation volume requirement. End of discussion.. This machine was made overseas, and no one here is trained on it.

This information will allow proper line size identification and the proper multi-stage pump selection. Direct and semi-direct operated valves operate with a pressure differential from 0 bar. No.809 Chang Xing Avenue, Chang Xing Economic Development Zone, Hu Zhou City, Zhejiang Province, China. These new pumps are direct replacements for the pumps currently being offered by the competition and are more energy efficient. Total volume of system to be evacuated lines, cups, leaks, etc. Today, vacuum suction cups are available in a broad range of materials, shapes, and sizes, which must be carefully selected based on the intended application. Central vacuum generator for gantry systems. They can create a very high vacuum, combined with a high evacuation volume. Main types of vacuum pump suction cups include: Used for handling flat or slightly rounded, rigid, smooth objects. Identify the lowest required vacuum, hold it there, and try not to exceed it. Our first suggestion to the plant was to change the software program so that the operating profile was on just the 15 percent of the time and off 85 percent of the time. We recommend unlubricated air. They can be integrated directly into the system due to their lightweight and compact design. Each palletizer has a robotic arm with six suction cups and two Venturi vacuum generators, both running and drawing 6 cfm at 60 psig. Cups are made from different composites, depending on the need. The new, clear filters have been added to the list of Becker Genuine Parts. Please keep in mind that solenoid valves are very sensitive to dirt and only work with clean liquids or air. To others, it is a constant waste of air.

This provided potential annual electrical energy savings of: This was only figuring the electric energy cost savings that goes immediately to the bottom line.

Air-driven Venturi vacuum generators have long been a viable option for fast-response, localized, vacuum-powered systems. By selecting 'Other', you can The reason is that dirt particles can settle in the vacuum generator and silencer when you use lubrication. What are the limitations? Becker Pumps Corporation100 East Ascot LaneCuyahoga Falls, OH 44223. differential. Vacuum generators are mainly used in pick and place robots in virtually all industries.

- Hoover Onepwr Battery Reset

- Powder Coating Services

- Chanca Piedra Plant For Sale

- Apollo Pex Crimp Tool Go/no-go Gauge

- Copal Tulum All Inclusive

- Commercial Fertigation Systems

- Fear Of God Essentials Pull-over Hoodie

- Shein Newness Tie Front Lettuce Trim Mesh Top

- Lowe's Electric Lawn Mower

- Spring Lake Resort Algonquin

- Commemorative Synonym And Antonym

- Avene Skin Recovery Cream Discontinued

- Blendtec Parts Diagram

- Cross Century Ii Black Lacquer