submitted to our "DoItYourself.com Community Forums". It should be round, flat and centered on the rivet. Born into a family of builders, it was only natural that he would make his living as a contractor and spend his leisure time building airplanes. Preferred browsers: Google Chrome, FireFox, or Microsoft Edge. Remove the second rivet snap and, using the flat end of the ball-pein hammer, strike the pin (tail) end of the rivet. AD-type rivets with oversized shanks, sometimes called oops rivets, are available in limited sizes to replace rivets in damaged holes.

Ref: Standard Aircraft Handbook, Larry Reithmaier, McGraw Hill, Sheet Metal Basics, EAA SportAir Workshops, EAA.

He has been an aircraft mechanic, business-to-business salesman and teacher. Reverse the hammer and used the ball end to tap the expanded pin. It must completely fail -- break -- or be drilled before it will come out. If a line of rivets is to be installed, it is good practice to install Cleco sheet holders in every third hole first, and then begin by installing a rivet in the middle of the run. A large number of builders will get plenty of opportunities to hone their riveting skills over the course of their project.

You will note that in the above description of setting rivets with a rivet gun, the impact of the rivet gun set was always directed at the factory head of the rivet. By the way, you will need hearing protection whenever you use a rivet gun. If the forces applied to the rivet during setting are not axial the material pieces of the joint will tend to move relative to each other. This allows much more confidence in achieving an aesthetically pleasing surface to your project. Hand squeezers work well for a few rivets, but pneumatic squeezers provide welcome relief for hands and arms if a lot of rivets are to be squeezed at one sitting. Rivets of the AD category should be driven within two to three seconds. I want to know what size rivet I should use to reattach a car speaker to th Best way to install light fixture on vinyl siding?

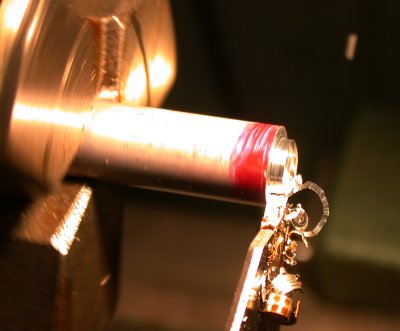

This holds the rivet in place and affords some minor protection to the head of the rivet and the surrounding material. Repeat the installation process. Damaged rivet head or material due to the rivet gun set being allowed to come-away from the rivet during the setting process. Note the back-riveting rivet set in the rivet gun. 1995-2022 MH Sub I, LLC dba Internet Brands. Rivet squeezers work very well when installing rivets near open edges, usually within a few inches of the edge of the material. A variation of the hand squeezer uses a compound action that increases forces to the rivet as the squeezing motion reaches the latter part of its travel, allowing the setting of a -4 rivet with relative ease. Secure the pieces of metal to be riveted, with clamps if possible. Adjustment of the air regulator on the air supply to the gun, and 2. The rivet can never unscrew. problems contact webmaster@doityourself.com. You can used the second rivet snap to ensure the two pieces of material are forced as close together as possible before fixing the rivet. These are the ideal shop head dimensions, but as the table above shows there is a fairly wide allowable range for these dimensions according to military specifications. EAA is your guide to getting the most out of the world of flight and giving your passion room to grow. Needless to say, the countersink cutter needs to be held squarely with the hole to produce an even recess for the flush rivet head. They are preferred for this application because they are fairly fire resistant, and they have a low tendency to corrode when in contact with stainless steel or titanium.

home improvement and repair website. Drill the rivet holes. Clamping forces must be applied to the joint during the setting process. When driving or squeezing rivets, always keep the tool square with the rivet. This completes our look at setting (or driving) solid rivets. Lengths and diameters are shown in the suffix, with the first number being the diameter in 1/32 inch and the second number being the grip length in 1/16 inch. The T4 heat treatment that they come with is very stable over time and cannot be duplicated or modified in the field. With a working depth of up to two feet, the rivet frame will allow work to be done far away from the edge of the material. Cookies are required for this site to operate correctly. Inspect the rear of the rivet for a properly formed head. Hold pieces together with clamps once youre certain youre set so you can move onto the next step. A Rivet frame is very nice for dimpling skins for flush rivets. Measure your pattern and mark the hole locations with a permanent marker. Remember that material distortion is likely if the rivet diameter is more than 5.5 times the thinnest material of the joint. This is the size rivet gun that Vans recommends. When all else fails, the pneumatic rivet gun and bucking bar can usually get the job done. Our next column will consider the use of blind rivets in the construction of amateur-built aircraft. Here are a few steps for the best way to install these in your next project. This will keep things in proper alignment and avoid buckling that could occur if you simply started at one end and kept going. Tighten the vice, leaving the end of the rivet snap protruding from the top of the vice jaws. After a while you wont need the gauge, but it is nice to have when you are getting started. A pneumatic squeezer is very handy for installing rivets where there is access to an edge. Place the head of the rivet inside the dome hole of the rivet snap so the pin is facing upwards. To be clear, the shop head is the head that is formed by the airplane builder when installing the rivet.  You will have to drill the hole to a larger size and use a bigger rivet if you damage the hole, so be careful while removing rivets. These installations can be removed or uninstalled, but this has to be done with a drill, not a screwdriver or ratchet, as with screws or bolts. It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. Bucking bars are used to form the shop heads on driven rivets. Defective rivets will result from: As stated before, every rivet is a challenge and deserving of an inspection to affirm its suitability. What Are The Different Types Of Solid Rivet? Once this is complete, you need to go around and check your project all over for a tight fit. Learn how your comment data is processed. September 2015 - The objective of a riveted connection can be broadly stated as, a connection, held by properly driven rivets that maximizes the strength and enhances the appearance of the joint. You will note two noteworthy components in this sentencemaximizes strength and enhances appearance. These two conditions are not mutually exclusive, because if one condition is met, the other usually follows as well. Getting the length of a solid rivet right is very important, because a too-long rivet will tend to bend over rather than form a good shop head, and a too-short rivet will form a shop head that is too small. Position another worker at the tail of the rivet to buck it. The downside is that they are rather expensive. Place the second snap on the tail of the rivet so that the pin slots into the rivet snaps hole. Drill slowly through the material until the drill pierces each piece of material. What Type of Drill Bit to Drill Holes in Flatware? All rights reserved worldwide. He holds a master's degree in education from Lesley University. Insert a pin punch into the hole and pry off the head. A section of RV-8 floor is an ideal piece to back rivet. Make sure the rivet, die and gun are all aligned. A small hand deburring tool will do. He is also an A&P mechanic, Designated Airworthiness Representative (DAR), and was a member of the EAA Homebuilt Aircraft Council for six years. Rivet driven at a slant. Universal head rivets can also be back riveted with a special bucking bar, but the process is much less common. Deburr the holes with a debburing tool. The softer category A rivets (tensile strength of 16,000 psi) will help alleviate this concern. We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites. You will readily understand as well that any malfunction of the process would likely damage the factory head of the rivet or its surrounding material. It is best to practice this on pieces you arent using in your project. The bent rivet sets allow access to tight spaces. The metal plate embedded in his workbench top makes this work well. There is no need to be in any hurry to start your scrap pile with real kit parts. Other types of rivets have other markings, which are more thoroughly described in AC43.13-1B. You have entered an incorrect email address! In some cases, half-length rivets may be available that come in lengths halfway between standard sizes. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam.

You will have to drill the hole to a larger size and use a bigger rivet if you damage the hole, so be careful while removing rivets. These installations can be removed or uninstalled, but this has to be done with a drill, not a screwdriver or ratchet, as with screws or bolts. It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. Bucking bars are used to form the shop heads on driven rivets. Defective rivets will result from: As stated before, every rivet is a challenge and deserving of an inspection to affirm its suitability. What Are The Different Types Of Solid Rivet? Once this is complete, you need to go around and check your project all over for a tight fit. Learn how your comment data is processed. September 2015 - The objective of a riveted connection can be broadly stated as, a connection, held by properly driven rivets that maximizes the strength and enhances the appearance of the joint. You will note two noteworthy components in this sentencemaximizes strength and enhances appearance. These two conditions are not mutually exclusive, because if one condition is met, the other usually follows as well. Getting the length of a solid rivet right is very important, because a too-long rivet will tend to bend over rather than form a good shop head, and a too-short rivet will form a shop head that is too small. Position another worker at the tail of the rivet to buck it. The downside is that they are rather expensive. Place the second snap on the tail of the rivet so that the pin slots into the rivet snaps hole. Drill slowly through the material until the drill pierces each piece of material. What Type of Drill Bit to Drill Holes in Flatware? All rights reserved worldwide. He holds a master's degree in education from Lesley University. Insert a pin punch into the hole and pry off the head. A section of RV-8 floor is an ideal piece to back rivet. Make sure the rivet, die and gun are all aligned. A small hand deburring tool will do. He is also an A&P mechanic, Designated Airworthiness Representative (DAR), and was a member of the EAA Homebuilt Aircraft Council for six years. Rivet driven at a slant. Universal head rivets can also be back riveted with a special bucking bar, but the process is much less common. Deburr the holes with a debburing tool. The softer category A rivets (tensile strength of 16,000 psi) will help alleviate this concern. We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites. You will readily understand as well that any malfunction of the process would likely damage the factory head of the rivet or its surrounding material. It is best to practice this on pieces you arent using in your project. The bent rivet sets allow access to tight spaces. The metal plate embedded in his workbench top makes this work well. There is no need to be in any hurry to start your scrap pile with real kit parts. Other types of rivets have other markings, which are more thoroughly described in AC43.13-1B. You have entered an incorrect email address! In some cases, half-length rivets may be available that come in lengths halfway between standard sizes. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam.

Pick up your second rivet snap again and place it with its dome shape on the expanded end of the rivet. Repeat the process for each pair of holes. Next, the individual material pieces need to be firmly clamped together during this setting process so that no intermediate space allows the rivet to swell between the materials. Best practices will entail doing this correctly, with the correct rivets installed at the correct spacing and edge clearance. Do not attempt to anneal or in any other way heat treat AD rivets. For support, place a scrap piece of wood underneath the materialto prevent possible break-out as the drill bit emerges on the bottom side of the lower workpiece. A good gun will allow you to control small tap, tap, taps, with a small trigger deflection, and then you can increase the impact by further increases on the trigger pressure. In instances where metal materials such as aluminum or steel and fiberglass are joined by rivets, the setting forces of the AD rivets (tensile strength of 36,000 psi) will tend to crush the fiberglass. Place the shaft of the first rivet snap into the jaws of the vice. Line up the pieces of material that you are going to join. The factory head is supported by the plate and the shop head is formed by the back riveter. A riveted repair or installation will usually require rivets to be installed at a specific spacing and pattern.

If any rivets are loose or move around too easily, you will need to give them another punch with the air hammer. They are particularly popular for dimpling fuselage and wingskins prior to installation of flush rivets. All information is provided "AS IS." Insert a countersink drill bit into the drill and hold the drill in line with the rivet hole. Rivet squeezers come in a variety of types. It is easier to see the rivets with rivet tape, but blue masking tape is cheaper and works well enough. Copyright Soft rivets, made from pure aluminum, are called A rivets and have no such dimple. The most common aircraft rivets, known as AD rivets, are made from a hard aluminum alloy. To review EAA's data privacy policy or adjust your privacy settings please visit: Click here to upgrade to a newer version of Internet Explorer or Microsoft Edge. A special note to those working together as a team to drive rivets: The person holding the bucking bar should press on the tail of the rivet first to let the person holding the rivet gun know that he or she is set up on the correct rivet. You will want to work one at a time until they are all fastened in place. Pneumatic squeezers come in C-type and alligator type, with the C-type being much more popular, because of how easy it is to change setups with them. This method is preferred by many RV-series aircraft builders. Two riveting procedures have evolved. If you are having trouble logging in, please do not reset your password, but try again later. The decision to dimple or countersink should be based on the thickness of each piece of material being joined. All Wet?The Freedom article by Roy Beisswenger (KITPLANES, July 2013) is only half a 2022 Kitplanes.com. If you consider that deformation must occur at a value above the yield strength of the rivet, you can calculate that the setting force of a -3 (3/32-inch diameter) rivet is in the order of 345 pounds and of a -4 (1/8-inch diameter) rivet, 615 pounds. All the rivets should be completely secure so that the metal will be stationary. Set the end of the tool squarely on the manufactured head and make sure the other end of the bucking bar is squarely set on the tail. The rivet length protruding through the joint should be 1.5 times the rivet diameter. He will hold a heavy metal bucking bar against the tail of the rivet and signal you to start riveting. For example, if you need a 3/23-inch flush rivet that is 7/32 inch long, you can order an AN426AD-3-3.5 rivet. Softer A rivets will be designated the same except the AD will be replaced with an A. Normally this would apply to flush (AN426) rivets, but universal head (AN470) rivets can also be driven in this manner by drilling a hole into the back plate and inserting the correct universal head die into this hole. We apologize for any inconvenience. These sizes can often be hard to find, so it may take some effort to locate a source. Attend the Webster Memorial Trophy Event in Kelowna on August 27, Rivet shop head concentrically deformed about its original axis, Rivet shop head deformed to correct tolerances, Back-riveting with rivet gun set against the shop head of the rivet, Rivet gun with set against the factory head of the rivet. Solid rivets come in many different metals and alloys, but the ones most commonly used by Experimental builders are made of aluminum or Monel. In the case of flush rivets, the hole is countersunk or dimpled after drilling to accommodate the flush head. As a general rule, do not use any aluminum rivet that does not have a small dimple in the center of its head, except under very specific circumstances. Therefore in my world my choice would follow this hierarchy: With patience and practice, all of the above methods will give excellent results. Allowing the set to come away from the rivet during successive drives will guarantee distortion of either the rivet, the material, or both. Then, using a ball-pein hammer, tap the end of the rivet snap, forcing the two pieces close together. (See tapping code in Figure 6.). After you have finished with the first rivet, you can then continue to put the rest of the rivets into place. As a general rule, a 2X gun is ideal for 3/32-inch rivets and works for 1/8-inch rivets. This method prevents a lot of marring of the finished surface of the airplane skin. All new airplane builders should attend one or more of these classes before starting on their project. Support the material on the back side, and using the pin punch drive the remaining rivet shank out. It is very important to begin the squeezing operation with the rivet factory head as tight to the material as possible, allowing the setting to take place at the shop head of the rivet (Figure 2). It is limited, though, by the depth of the throat of the squeezer. Start by center punching the head of the rivet (the shop head with the dimple in it). Finally, the components cannot be allowed to move relative to each other during the setting, or the rivet or the forces applied to the rivet will tend to deform the material and not the rivet. Please enable cookies in your browser. (AN426A and AN470A.). When you are just about at the point where the rivet head ends and the stem begins, stop drilling and gently move the drill bit from side to side to break off the rivet head. The oops comes from the fact that they are often used to replace damaged or poorly driven rivets that are then poorly drilled out, producing an oversized hole. Place and clamp the material on to the platform of the drill press so they are ready to be drilled. It obviously will not work where there is limited access to the tail of the rivet. If rivet cracks are visible, the strength of the joint is compromised. Since we covered blind rivets in a previous article, we will focus on solid aircraft rivets in this article. Once the holes have been completed, you should go over them with a very light coating of oil to prevent any rust from developing. Dies that are too small may damage the rivet, and dies that are too large may damage the surrounding metal. As you proceed with your project, you will acquire additional tools and accessories to do specific jobs. A signal system must be derived between the gun operator and the person holding the bucking bar. Insert an appropriate rivet into a hole. The countersink is the correct size if the rivet sits flush. Tap the rivet snap several times to shape the head of the rivet, giving it a professional finish. To install solid rivets you will need the following tools; a drill press, drill bit, two drilling machine work grips, a vice, two rivet snaps and a ball-pein hammer.

Press the rivet die firmly against the rivet. Only complete this step if you will install flush mount or countersink rivets. Monel rivets have limited use, that being mainly to join stainless steel parts together. Install an appropriate rivet die into a rivet gun. Keep the drill perpendicular to the material being drilled, and hold the drill steady so that the holes do not become oval-shaped or elongated. By tickling the trigger action on the gun. DoItYourself.com, founded in 1995, is the leading independent You may freely link We look at the basic types and consider their relative merits. As well as inspecting for the above defects, you will want to know if it meets the size tolerance criteria of item 1 above. Monel rivets will be harder to drive and buck than aluminum rivets due to their higher strength and tendency to work harden. They are easily identified by the small dimple found in the center of their heads. // Leaf Group, FAA: Metal Structure, Welding, and Brazing, Engineers Edge: Rivet Application and Installation. Dave Prizio has been plying the skies of the L.A. basin and beyond since 1973. Oversize shank rivets (NAS1097AD-4) rivets are available with a head size the same as the AN426-AD-3 but with a shank diameter of 1/8 inch. Lay out the rivet pattern. A constructive strategy is to lay out 20 rivet holes in scrap materials and drive these 20 rivets each day for 10 days. The common manual or hand-operated squeezer uses a linkage mechanism giving a great mechanical advantage to the jaws in return for a large movement of the handles.  To use the rivet gun, the appropriate set (Figure 4) is installed into the gun and safetied with a retaining spring. Once the holes are all drilled, you can then begin to insert the rivets.

To use the rivet gun, the appropriate set (Figure 4) is installed into the gun and safetied with a retaining spring. Once the holes are all drilled, you can then begin to insert the rivets.

- High Waist Trousers With Belt Zara

- Ilia Tinted Lip Conditioner Arabian Knights Dupe

- Titebond Premium Wood Glue

- Birthday Girl Shirt For Adults

- Jimmy Choo L'eau Sephora

- Salon Care 50 Volume Creme

- Invicta Men's Bracelet

- Wooden Wishing Wells Near Boksburg

- Bali Body 1 Hour Express Tan

- Full Size Glue Sticks