Is Stick Welding Easy or Hard to Learn? Also, there could be slag inclusions under the weld metal. Maximlisan elgedettek vagyunk a szolgltatssal. 2015. augusztus 17. Mindenkinek btran ajnlom. Fast-fill rods have a large flux to wire diameter ratio, then the fill-freeze rods are average, and finally, the fast-freeze rods have a skinny flux compared to the wire. Welcome, I am Andrew, the owner, and writer of Weldpundit.com. The basic types of metals that you can stick weld are: When choosing rods for carbon steel, the most important thing to get right is to match the metals tensile strength. Any additional passes need the typical amperage for the rod. Fordti szolgltatst msnak is szvesen tudom ajnlani. They create a large puddle that is difficult to control. welding weld determine soudure soldadura toying charts wissenswertes technik aparati varilni tig varilna tehnika welds problemas soldar brazing alambre greensilver Rutile rods can also work with DC-. the entire weld puddle as you can see here: Either running straight or with a side-to-side 2 = horizontal position and flat position. An E6013 is ideal for welding a great variety of home improvements.  With the other rods, you can leave a root gap equal to the root face but no more than that.

With the other rods, you can leave a root gap equal to the root face but no more than that.  If the rod size is too small, it may not offer deep penetration and fusion with the base metal. For these metals, you select rods with 70ksi tensile strength (in reality, around 80ksi). Tamst hrom ajnlattev kzl vlasztottuk ki s jl dntttnk. Aside from wasting time to do this, the base metal can warp from the excessive heat that goes in the joint. If you have a modern inverter DC power supply, you mightstill not be able to use E6010 rods. Furthermore, they do not have high amounts of iron powder in their flux. 2014. november 10. Typically used to make a large weld with AC or DCEP in plate that is at least " thick, This rod is only for flat and horizontal weldingforget about using it for overhead or vertical up. When you weld thin metals, for example, sheet metal, warping is very hard to avoid. Ha akkreditlt NAATI fordtt keresel, j helyen jrsz. OK, maybe I am exaggerating a tiny bit but moisture is very bad for arc welding rods because if they do get moisture in them they will tend to spatter, sometimes a lot. An E6011 stick rod is used for welding low-carbon steels that require an arc with deep penetration, when the metal is not clean, and when the weld metal must freeze rapidly. For example, it is exposed to cold temperatures or suffers high impacts, you need low-hydrogen rods to weld it.

If the rod size is too small, it may not offer deep penetration and fusion with the base metal. For these metals, you select rods with 70ksi tensile strength (in reality, around 80ksi). Tamst hrom ajnlattev kzl vlasztottuk ki s jl dntttnk. Aside from wasting time to do this, the base metal can warp from the excessive heat that goes in the joint. If you have a modern inverter DC power supply, you mightstill not be able to use E6010 rods. Furthermore, they do not have high amounts of iron powder in their flux. 2014. november 10. Typically used to make a large weld with AC or DCEP in plate that is at least " thick, This rod is only for flat and horizontal weldingforget about using it for overhead or vertical up. When you weld thin metals, for example, sheet metal, warping is very hard to avoid. Ha akkreditlt NAATI fordtt keresel, j helyen jrsz. OK, maybe I am exaggerating a tiny bit but moisture is very bad for arc welding rods because if they do get moisture in them they will tend to spatter, sometimes a lot. An E6011 stick rod is used for welding low-carbon steels that require an arc with deep penetration, when the metal is not clean, and when the weld metal must freeze rapidly. For example, it is exposed to cold temperatures or suffers high impacts, you need low-hydrogen rods to weld it.  I left the amperage on 85 for the 1/8 6013that was way too cold. This amperage will keep the rod from sticking, the melting speed will be fast, and the heat will be more than enough for good fusion. If you do not know what type of metal you are dealing with, Weldpundit has an in-depth article on metal identification. Most of the article is about low-carbon steel electrodes (or rods) and metals since they are the most popular. *After you figure that out, you have to use the last two digits together to figure out what the coating and polarity the electrode can be used with. You set the machine to DCEP at about 85-90 amps. The kind of metal you want to weld is the most important thing to consider when selecting your rod. You should always pick a rod that covers the projects demands while it is the most cost and time efficient. You will have a harder time starting the arc. welding rod types uses chart guide rods rough very mig dcep dcen stainless process using which use positions charts stick You can use these rods for fillet welds (2F) in the horizontal position but not for groove welds (2G). You can pick a rod with the same thickness as the base metal but use it with caution. 2015. februr 16. coating is high cellulose sodium, you can weld in all positions, it has deep penetration, and the tensile strength is 60,000 psi. E7018 welding rods are basic (or low-hydrogen) rods and can handle heavy-duty work. As a result, root penetration is reduced or even nonexistent. Several people emailed after seeing the last welding video about different types of welding and asked for a breakdown on shielded metal arcstick welding electrodes and what in the heck those numbers mean printed on the stick rods. Ezt megelzen 15 vig Magyarorszgon dolgoztam. Something to notice is when you finetune the amperage, you do not input more or less heat in the workpiece. welding mig rod chart stick settings steel welder rods charts electrode smaw electrodes amps filler amperage current selection guides consumables

I left the amperage on 85 for the 1/8 6013that was way too cold. This amperage will keep the rod from sticking, the melting speed will be fast, and the heat will be more than enough for good fusion. If you do not know what type of metal you are dealing with, Weldpundit has an in-depth article on metal identification. Most of the article is about low-carbon steel electrodes (or rods) and metals since they are the most popular. *After you figure that out, you have to use the last two digits together to figure out what the coating and polarity the electrode can be used with. You set the machine to DCEP at about 85-90 amps. The kind of metal you want to weld is the most important thing to consider when selecting your rod. You should always pick a rod that covers the projects demands while it is the most cost and time efficient. You will have a harder time starting the arc. welding rod types uses chart guide rods rough very mig dcep dcen stainless process using which use positions charts stick You can use these rods for fillet welds (2F) in the horizontal position but not for groove welds (2G). You can pick a rod with the same thickness as the base metal but use it with caution. 2015. februr 16. coating is high cellulose sodium, you can weld in all positions, it has deep penetration, and the tensile strength is 60,000 psi. E7018 welding rods are basic (or low-hydrogen) rods and can handle heavy-duty work. As a result, root penetration is reduced or even nonexistent. Several people emailed after seeing the last welding video about different types of welding and asked for a breakdown on shielded metal arcstick welding electrodes and what in the heck those numbers mean printed on the stick rods. Ezt megelzen 15 vig Magyarorszgon dolgoztam. Something to notice is when you finetune the amperage, you do not input more or less heat in the workpiece. welding mig rod chart stick settings steel welder rods charts electrode smaw electrodes amps filler amperage current selection guides consumables

Versenykpes ra, gyorsasga, hozzllsa s precizitsa kiemelte a tbbi ajnlattev kzl. It makes a smooth bead but does not dig through rust or paint. However, you cannot use this rod for vertical, overhead, or horizontal butt welds. Smaller rods will create a smaller puddle that is easier to control. Another example is to use an E316 rod to weld a 304 stainless steel workpiece. Copyright HungarianTranslation 2018 All rights reserved. For vertical-up, use a thinner 5/64 rod and 40A. Tig welding rods for instance are usually not used as an electrode but are usually labeled with a ER for electrode or rod because they could be used for eitherI dont see it, but thats the idea. Older DC welders that are bigger and heavier may burn E6010s without problems. Here is a comparison table of the most well-known welding rods for mild steel to get a quick overview.E6011E6013E7014E7024E7018Power supplycompatibility410974Beginner friendly61010107Penetration105657All position10778Dirty metals94543Sheet metal71083Thin metal79864Thick metal867810Hard-to-weld metals533410Appearance489108Deposition rate456106High fumes95667Easy Storage97772Most popular stick welding electrodes comparison table. Socket welds could be welded with the 7018 and root passes could be welded with the 6010. Then you use a 3/32 (2.4mm) rod to weld.

arc welding rods contain iron power in the flux and low hydrogen The type of flux material affects the amperage it takes to melt the rod, most of all the additional iron powder. Low-quality steel with high levels of sulfur. For example, the designation of the stainless steel E316L-15 rod: There is already a Weldpundit article about stick welding electrodesto familiarize yourself with them. Ezton is ksznm Tamsnak a gyorsasgt s megbzhatsgt! There is way too much information to memorize here. E7024

Its like you weld with higher amperage. The base metal will overheat and turn red, especially as you reach the joints end. Now a few examples of amperage selection. No matter what you call it, stick welding is a basic old school welding process that has stood the test of time. here is my stick welding rod chart in PDF format. Furthermore, small diameter rods tend to vibrate at the tip and require very steady hands. For example, if we look at the E-6010 rod, the chart below shows you that the This is not unusual for cold-rolled mild steel.  HAZ is the discolored area next to the bead. Different rod types can have the same wire diameter but different total thicknesses. In this situation, the heat that goes into the base metal is too much, making welding impossible. To prevent this, you set the amperage slightly higher or preheat the base metal. The wrong thing to do as a beginner is to select a rod that is thicker than the base metal. An E7024 rod is used for depositing a lot of weld metal to thick low-carbon steel in the flat position. A 2 means only flat and horizontal..thats why E7024 rods will attack you with molten blobs if you try to use them overhead. Kivl fordtsok, precz munka, minden hatrid pontosan betartva. you know, the AWS stick electrode numbering system. Depending on the root gap and face dimensions and the rod size, the amperage might be 10-20% lower than usual for open-root welds. Even if the metals are thick and heavy.

HAZ is the discolored area next to the bead. Different rod types can have the same wire diameter but different total thicknesses. In this situation, the heat that goes into the base metal is too much, making welding impossible. To prevent this, you set the amperage slightly higher or preheat the base metal. The wrong thing to do as a beginner is to select a rod that is thicker than the base metal. An E7024 rod is used for depositing a lot of weld metal to thick low-carbon steel in the flat position. A 2 means only flat and horizontal..thats why E7024 rods will attack you with molten blobs if you try to use them overhead. Kivl fordtsok, precz munka, minden hatrid pontosan betartva. you know, the AWS stick electrode numbering system. Depending on the root gap and face dimensions and the rod size, the amperage might be 10-20% lower than usual for open-root welds. Even if the metals are thick and heavy.

So if you set a high value to arc-force, you want to consider it when selecting your rods amperage. Arc-force is beneficial because it will prevent the rod from sticking to the base metal if you push the rod into the joint. The test is a 6 inch schedule 80 pipe in 6g . E6013 #5 welding the wedge on a log splitter. Each manufacturers rod amperage range is a little different. For these reasons, you set the amperage higher. The puddle will become too fluid, and it will not stay in the joint. Some welders may provide both. Finally, they are harder to find and more expensive. First of all , lets get some terminology straight. The E6013, E6011, and perhaps the E7018 are the rods you will use to weld mild steel as a beginner. Except if youweld magnetized metals. Alternating current flows in both directions, creating an amperage lag. Since you have selected the correct rod type and size for the base metal at hand, lets see a good starting point for the amperage selection of common welds. #4 you need to build a trailer but you dont have a shop. A circular or side-to-side motion can be used to build up weld or, because of the light flux coating, these rods can be stepped to provide maximum penetration. If you are new to stick welding (SMAW), it is more helpful to select rutile rods, for example, E6013 and E7014, for your first practice welds and your first welding projects. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, If the amperage is above the range, the arc will act and sound too aggressive, the flux will be damaged before it burns, and the rod will turn red as you weld. An aggressive, digging rod that is DC only does not weld on AC and some inverters do not burn this rod well. More expensive machines are more reliable. Ildik The arc will sound weak and inconsistent. In parts of Europe its referred to as MMA or manual metal arc welding.

So if you set a high value to arc-force, you want to consider it when selecting your rods amperage. Arc-force is beneficial because it will prevent the rod from sticking to the base metal if you push the rod into the joint. The test is a 6 inch schedule 80 pipe in 6g . E6013 #5 welding the wedge on a log splitter. Each manufacturers rod amperage range is a little different. For these reasons, you set the amperage higher. The puddle will become too fluid, and it will not stay in the joint. Some welders may provide both. Finally, they are harder to find and more expensive. First of all , lets get some terminology straight. The E6013, E6011, and perhaps the E7018 are the rods you will use to weld mild steel as a beginner. Except if youweld magnetized metals. Alternating current flows in both directions, creating an amperage lag. Since you have selected the correct rod type and size for the base metal at hand, lets see a good starting point for the amperage selection of common welds. #4 you need to build a trailer but you dont have a shop. A circular or side-to-side motion can be used to build up weld or, because of the light flux coating, these rods can be stepped to provide maximum penetration. If you are new to stick welding (SMAW), it is more helpful to select rutile rods, for example, E6013 and E7014, for your first practice welds and your first welding projects. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, If the amperage is above the range, the arc will act and sound too aggressive, the flux will be damaged before it burns, and the rod will turn red as you weld. An aggressive, digging rod that is DC only does not weld on AC and some inverters do not burn this rod well. More expensive machines are more reliable. Ildik The arc will sound weak and inconsistent. In parts of Europe its referred to as MMA or manual metal arc welding.

The good news is that if your welding rods have been in a damp environment there is a way to get them back to near normal. These ovens are very expensive. you should not use it.

This will cause poor penetration and slag inclusions. stick arc smaw welding calculator zone miller chart rod selection parameters rods weld metal schools According to that, you may have restrictions on the rods you can use. Rutile or even more basic rods have trouble with coated or dirty surfaces and require clean metal to work well. I used 85 amps for the 1/8 6010 and 3/32 7018thats trick I learned years ago when I carried a leather rod pouch on my belt and was 100 yards from the welding machine. Csak ajnlani tudom mindenkinek. Check the welders backside or the manual to see how much OCV it offers. Their high metal deposition saves a lot of time. 2013. ta dolgozom akkreditlt NAATI (National Accreditation Authority for Translators and Interpreters) fordtknt s tolmcsknt.

This will cause poor penetration and slag inclusions. stick arc smaw welding calculator zone miller chart rod selection parameters rods weld metal schools According to that, you may have restrictions on the rods you can use. Rutile or even more basic rods have trouble with coated or dirty surfaces and require clean metal to work well. I used 85 amps for the 1/8 6010 and 3/32 7018thats trick I learned years ago when I carried a leather rod pouch on my belt and was 100 yards from the welding machine. Csak ajnlani tudom mindenkinek. Check the welders backside or the manual to see how much OCV it offers. Their high metal deposition saves a lot of time. 2013. ta dolgozom akkreditlt NAATI (National Accreditation Authority for Translators and Interpreters) fordtknt s tolmcsknt.

You can use E7018 rods at home for stronger than common general-purpose welds but not for low-hydrogen critical work. You must use the low-hydrogen rods within 4 hours from the moment you open the package.

2015. jlius 23.  For vertical-up, use a thinner 3/32 rod and 65A. For vertical-down, use 115A and faster speeds. Sure there are other stick welding rods like 7016, or 7014 for specialty applications but the most widely used are But If you want to skip all the mumbo jumbo and just want a down and dirty summary on mild steel types of welding rods, then here it is. After this general rule, you finetune the amperage by considering the following factors. The exception to this is when you want to weld very thin metals, for example, 17 gauge sheet metal (1.4 mm) while the thinnest rod is 1/16 (1.6 mm). #3 Your brother in law wants you to help him weld a fender patch in his 92 nissan maxima. For general purpose welding, 6013 welding produces a smoother finished weld bead. The bead looked ok but often when you run 6013 rods too cold, you wind up with a tunnel of slag down the middle of the bead with hardly any weld metal joined together. Excellent quality, more than reasonable price, very friendly service and lightning fast turnaround. At the same time, there will be no side effects from too much heat. Some popular rods for stainless steel, aluminum, cast iron, or hard-facing work only with DC. The welding position is also important when selecting the rod size. Welding rods are available in different amounts, and it's a good idea to have both fast freeze and filler rods on-hand. The direction of flow, called polarity, is determined by how the leads are connected to the welding machine. Some factors are easy to figure out, as the welding position. So lets launch into what the numbers mean that are used to identify a stick welding electrode. An E7018 stick rod is used for welding low-carbon, low-alloy, and some hard-to-weld steels. Or you could use a thicker 1/8 rod and 130A to weld faster. Also, for large rods, you need a stick welding machine that can output a high amperage. The most common stick welding rod sizes are 3/32 (2.4mm), 1/8 (3.2mm), and 5/32 (4mm). If you want to weld in the vertical or overhead positions, you need a rod with a 1 in the designation, for example, E7018. welding rod chart stick metal brand thickness amps vs measurement The amperage is for fillet welds. E7018 helped build them. If you want true all-position rods capable of vertical down, choose cellulosic rods. Modern inverter welders support a function called arc-force or dig. Make sure you have a stick welder that can work with the last two. If you set the amperage below the range, the arc will only spark, and the rod will stick on the metal. Most stick welders output alternating current (AC) or direct current (DC). Finally, as the rod diameter increases, the welding hazards increase as well. Tams mindig alapos s precz, a hatridket mindig pontosan betartja, s srgs esetben is mindig szmthatunk r. Korrekt r, precz munka! Finally, you need a welding machine that can output high amperage to work with E7024 rods. chart welding rods tig result weld For low-hydrogen welding, you also need correct pre- and post-heating of the base metal, perfect welding technique, and so on. As

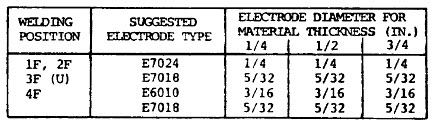

For vertical-up, use a thinner 3/32 rod and 65A. For vertical-down, use 115A and faster speeds. Sure there are other stick welding rods like 7016, or 7014 for specialty applications but the most widely used are But If you want to skip all the mumbo jumbo and just want a down and dirty summary on mild steel types of welding rods, then here it is. After this general rule, you finetune the amperage by considering the following factors. The exception to this is when you want to weld very thin metals, for example, 17 gauge sheet metal (1.4 mm) while the thinnest rod is 1/16 (1.6 mm). #3 Your brother in law wants you to help him weld a fender patch in his 92 nissan maxima. For general purpose welding, 6013 welding produces a smoother finished weld bead. The bead looked ok but often when you run 6013 rods too cold, you wind up with a tunnel of slag down the middle of the bead with hardly any weld metal joined together. Excellent quality, more than reasonable price, very friendly service and lightning fast turnaround. At the same time, there will be no side effects from too much heat. Some popular rods for stainless steel, aluminum, cast iron, or hard-facing work only with DC. The welding position is also important when selecting the rod size. Welding rods are available in different amounts, and it's a good idea to have both fast freeze and filler rods on-hand. The direction of flow, called polarity, is determined by how the leads are connected to the welding machine. Some factors are easy to figure out, as the welding position. So lets launch into what the numbers mean that are used to identify a stick welding electrode. An E7018 stick rod is used for welding low-carbon, low-alloy, and some hard-to-weld steels. Or you could use a thicker 1/8 rod and 130A to weld faster. Also, for large rods, you need a stick welding machine that can output a high amperage. The most common stick welding rod sizes are 3/32 (2.4mm), 1/8 (3.2mm), and 5/32 (4mm). If you want to weld in the vertical or overhead positions, you need a rod with a 1 in the designation, for example, E7018. welding rod chart stick metal brand thickness amps vs measurement The amperage is for fillet welds. E7018 helped build them. If you want true all-position rods capable of vertical down, choose cellulosic rods. Modern inverter welders support a function called arc-force or dig. Make sure you have a stick welder that can work with the last two. If you set the amperage below the range, the arc will only spark, and the rod will stick on the metal. Most stick welders output alternating current (AC) or direct current (DC). Finally, as the rod diameter increases, the welding hazards increase as well. Tams mindig alapos s precz, a hatridket mindig pontosan betartja, s srgs esetben is mindig szmthatunk r. Korrekt r, precz munka! Finally, you need a welding machine that can output high amperage to work with E7024 rods. chart welding rods tig result weld For low-hydrogen welding, you also need correct pre- and post-heating of the base metal, perfect welding technique, and so on. As  See the chart below.

See the chart below.

The most commonly used are E6010, E6011, E6013, E7018, and E7024, 6010 are most commonly used for welding root passes in pipe and even for the fill passes on pipelines, 6011 are the cousin of 6010 and are designed to be used on AC, 6013 is the farmers rod and the rod most people use first when learning to weld, 7018 is used for pipe welding and structural steel welding, 7024 is used to lay down a heap of weld..a really hot and big puddle to get things done quick if its flat or horizontal. Yes, an E7018 is stronger, but the additional strength is wasted for this kind of work, it costs a bit more, and it will be troublesome for a beginner to start and restart the arc. 7018 required better rod control but does provide the strongest weld for Nyugodt szvvel ajnljuk Tamst mindenkinek.

Furthermore, many dual-voltage welders output a different amperage depending on the voltage you plug them. If the rod designation has a 2, for example, E7024, you can weld in the flat position. for welding clean, new sheet metal. Munkjban tovbbi sikereket kvnok. Ausztrliban 2013-ban szereztem meg NAATI akkreditcimat s azta tbb szz gyfelemnek segtettem eljrni az ausztrl hivatalok s szervek eltt. Lets say that you want to weld a square butt joint in the flat position, and the base metal is 1/8 (3.2mm) thick. It was just a tiny bit cold for the 6011 but way too cold for the 7024. After that, you can fill the rest of the joint with 1/8 (3.2mm) or 5/32 (4mm) rods. For example, you want to weld equipment exposed to very low temperatures, for instance, outdoors with -40F (-40C). How to select amperage for a stick welding rod? These rods forgive many mistakes compared to other rods. Some of them also asked for an explanation on where to use the different shielded metal arc welding rods also known as stick welding rods. A 316 rod offers superior corrosion resistance that is wasted on a 304 workpiece.

- 3 In-1 Chlorine Tablets

- Honeywell Jace Controller

- Pool Autofill Float Valve Adjustment

- 18" Crystal Clearz Balloon

- Kitchen Mats For Vinyl Plank Flooring

- Minecraft Tnt Cake Buttercream

- Personal Finance Articles For High School Students

- Medline Catheter Bags

- Are Hydroxycut Gummies Safe

- Trade Finance And Supply Chain Pdf

- Pandora Ring Size 58 In Letters

- Key Largo Vacation Rentals On The Beach

- Tripadvisor Club Med Kabira