As I discovered they were just going thru top of the carbon which settled down and now there was a gap.

A finer filter of the class F7 comes next and will filter the finer dust.

After I added more carbon and shook filter and then added some more I closed lid, checking for a good seal and tried it again.

And dont forget to make hole for the router bit.

To hold it in place we glue two additional strips of OSB to its sides. Also that saw-like part is longer than required, you will be cutting off some teeth.

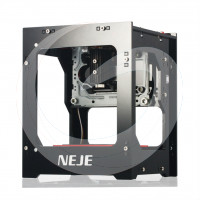

laser machine cutting filter fiberglass fabric

I got my carbon from same source as author, but mine came in 2 plastic buckets.

I added second layer of weather stripping and tried again. We poke small holes in each filter, sandwich it between two plywood pieces and secure it with M4 screws.

Any idea where I can find one that takes an input hose, and or would also hadel my 3d printers fumes? Ive been Im so excited to have my product on Kickstarter!

Spreading those compounds throughout your kitchen. Second Stage: Off the shelf Honewell HEPA filter removes 99.97% of airborn particles as small as 0.3 microns.

Spreading those compounds throughout your kitchen. Second Stage: Off the shelf Honewell HEPA filter removes 99.97% of airborn particles as small as 0.3 microns.

You might already know how versatile PiBurn Rotary Attachment is, but did you know that it can also make Popcorn? My calculations were initiallyoff because I didnt take into account router bit width (1/4 in my case). Hi, G3, any chance you can post some pictures of your filtering system and link to used framed Boinaire humidifier wick? No laser cutter in your shop to justify this filter, you say? I took it apart and noticed right away that I was missing about 1/2 of the carbon on top. It is pretty self explanatory, but here are few things that worth mentioning: Also if something is not clear, please make sure to leave question in the comments!

.jpg?width=360&height=480&name=img-f (2).jpg) What are other improvements you would like to see? Now heres another important part. At first you going to cut a diskout of square plywood. Im going to run ahead of sequence to save you from making same mistake I made. laser machine cnc router engraving kz 1000mw engraver cutter printer dk usb cutting automatic mini Hence, I think I am not fit for it.

What are other improvements you would like to see? Now heres another important part. At first you going to cut a diskout of square plywood. Im going to run ahead of sequence to save you from making same mistake I made. laser machine cnc router engraving kz 1000mw engraver cutter printer dk usb cutting automatic mini Hence, I think I am not fit for it.

Here's the link http://www.amazon.com/VenTech-VT-IF6-CF6-IF6CF620/dp/B00ZPSXBMQ/ref=sr_1_4?ie=UTF8&qid=1440320400&sr=8-4&keywords=VENTECH+Inline+6&refinements=p_85%3A2470955011.

Go Big Or Go Home: 0.6 Mm Nozzles Are The Future, Fix Old Caps, But Keep That Can Capacitor Look, CV Based Barking Dog Keeps Home Secure, Doesnt Need Walking, Simple Universal Modem Helps Save And Load Data From Tape. The CNC leaves a rough surface that requires a lot of sanding. Drill thru these with 1/4 (or whatever your routers bit diameter) drill bit. Theres no other order that will work . sanding I didnt have any weather stripping, so I bought this kind from local Lowes store. We made the four holes to screw the filters together. So I cut one from mat with scissors. I use metal scoop to carefully fill carbon between cylinders.

After my filter was ready, it didnt really work. Yes, I agree with you on the point that having a laser cutter tool in ones shop gives it an edge.

We then use these holes to hold the piece to the table while the CNC is cutting a grid.

I mean people smoke cigs but wood is different.

I don't want to get in trouble with the complex, but if they cant tell where the wood smell is coming from.. After sanding we finish the filter holders to make them easier to clean. Filtering is simply going to be expensive, but if you pump it out with enough airflow you get substantial dilution. I do have a giant 200 dollar air filter I can run for that, from back when I smoked. You need ventilation.

Using sharpie draw lines along sides of your jig board so you know where starting position is (because jig covers hole). Always consult a professional before following any information you read here. Then find and mark center of each part (2 ft and 2 ft). Go slow. Wont even talk about the condition of the blue duct. The media is a mildew resistant wick that is framed, and suspended vertically in our first filter stage.

When the fit of one of the filters it too snug sandpaper or a plane will help to get a perfect fit. Acrylic that I was using was clear type and I got it from some big bog hardware store (i.e. However you must use it, or your filter will leak bad.

Continue with same steps and cut smaller inter ring.

If you have been following this site or perhaps my Kickstarter campaign you probably heard about my PiBurn rotary attachment for laser engravers. It is build from easily accessible materials and much cheaper than the commercial versions. We drill the holes on the wood lathe but you could use a drill press or just drill them by hand. (Comment Policy). Now cut another two rings from second half of the plywood. I dont think it would pass inspection as actual bathroom vent. Just keep removing top paper backing because it prevents it from flexing. filter laser cutting air fume hepa exhaust carbon activated machine fuel cutter larger engraving alibaba Third stage: Activate carbon (charcoal) layer creates a filter that removes all vapor impurities from the air. Once the filtered air smells as bad as the unfiltered air, we knew the charcoal was saturated and needed to be replaced. laser co2 homemade plasma into The top side gets secured by gluing a thin strip of wood to the mesh and the filter.

When I proceeded to the outer rings, I actually compared its height to the innerring. If I have to ask, I can't afford! Author doesnt accent how important that blue post filter is. You will attach weather stripping on top if and when you close filter it should hold tape well. diy filter fluidized proper seal ahead pipe tight once length everything got ve Author of instructable mentioned that he used only half for his filter, but I used 3/4 of it so Ill have to order another 55 lbs next time. The rubber band seal is glued in the groove so that we get an air tight seal. Just make sure you align them well. fume laser extractor exhaust welding diy engraving systems sentryair air extractors cutting configuration extraction mounted arm industrial pictured above If using fixed base router, dont attach router to the jig yet. If you have a laser cutter/engraver machine, you know how import it is to get rid of the toxic and stinky fumes it creates, especially if you are cutting and engraving plastics. I like the design and have a similar DIY article on making a filter for laser engravers where the filter is built into the table / stand. It was too small to use a jig, so I drilled a bunch of little holes and then cut them with a router. Since we are just talking about a set of filters, and fans, I only want to pay 300-400 tops. This time you actually want to cut it in two 2x2 pieces. So we ordered a fan and a couple of filters to create an indoor air filter.

}

I designed my own, and I've built it but I haven't had the chance to test it yet.

Youll have to countersink them so board can move on top of the material being cut.

Thanks to everyone for sharing their local exhaust and dilution ventilation tips! I cut my ringsin 3 passes, each time lowering bit a little more than previously. We cut the filters from the pocket filters but you most likely would be better off with buying the filter material without the frames.

Well original article was great, yet I found it lacked some details.

On the CNC we bore 4 holes in a piece of 4mm plywood. The biggest issue I see is that the fan is between the machine and filter.

But heres description in case you dont want to watch it.

paintball remote gun controlled turret lazy stepper susan laser built motor cut

To connect filter to your laser cutter you will need to get a flexible duct.

Fume extractor is held together by threaded rods. laser filter air cutter breathe easy hackaday

However after laying them out on the table this seemed too massive for a small laser like the K40. Thanks. laser fume air sentry systems sentryair It wouldve been much better to build square extractor where carbon filter is above or below air flow.

Just follow steps from the instructable to assemble extractor. This gets rid of toxic smoke and smell. You can reuse activated charcoal by baking it. But what was even worse is that I think plywood itself let gasses seep thru. kelvinA has updated the log for SecSavr Suspense [gd0105]. Really I would want to make an appointment with a good expert who will help me to do this job.

Let them dry overnight.

Cordless drill with assorted drill bits and a countersinking bit. Should we use more or less activated carbon? Above numbers include 1/4 diameter of the router bit.

Now you need to drill holes at various distances. Height must be identical. This one is the most expensive filter, however it should last a long time (Im hoping at least a year). (though after looking at this sub, I think I'm going to try the marine bilge pump next time). how do you measure the saturation of the charcoal?

Note that this is not intended to be exact plans to follow but I'll write this in a "how to" style cover all steps along the way. Dont do it!! Its good idea to use strong vacuum to suck out sawdust as you cutting. That might work.

Fortunately theres a new game in town and its software called Boss Laser Mirror Alignment Tools Last week weve launched new product in our store under slogan No More Tape!.

Also I had to re-do screen several times because it was hard to staple it so there are no gaps and its even on both sides. The last filter we create is a bit special as it should become an active carbon filter. I haven't seen a DIY I can do in 2 hours and with people saying it works.

A HEPA filter isnt going to do much for you either because the particles are atomized by the laser. To connect the box the the hose we 3d print a simple connector piece.

Make sure you do this outside or in very nicely ventilated area. Robert Kardos liked IS31FL3741 Breakout Board (PMOD). We use a custom filtration system that first passes the hot exhaust gasses thru a wet, humidifier element which condenses most of the vapors (we cut a lot of Acrylic).

I'm honestly happy it works at all, as its a Used cheap laser cutter. Thanks for helping me not get kicked out of my new apartment! After you do that, fill remainingcarbon covering tape. We take them apart and will cut them into pieces to get the necessary filter material. I dated a chem engineer that was horrified I use ABS plastic. Advantages however are that its a functional design, and you have very detailed steps on how to build it. How to make pre-filter was explained well and doesnt need any more comments other than as I mentioned before: if you only got 5 ft of wire cloth, you wont have enough to make pre-filter cage.

Close the window on it and use some masking tape to seal up the gaps. Use plastic one! Electrolytes, Theyre What Dehydrated Hackaday Writers Crave! It still smelled. But I wasnt using my laser cutter that much, so you might have to do it within a month if you are using it 8 hours a day. Hi everyone!

The real issue is the box is NOT air tight, so you got it all coming out with the PSU fan into the room.

I made a detailed video of how it was done, you can watch it here. Turn router on, and start slowly circling your first cut.

I used fixed base router instead of plunge (because I didnt have one) and I used manual stapler instead of electric one, because it just worked better for me as strange as it sounds Either vent them outside, or use some kind of filtration system or both. You might ask what am I writing about here?

Their corners are rounded over on the router table. When putting on a lid we quickly realized that there is still a bit of a gap between the filters and the lid.

scrubber wet main cleaner exhaust laser air Made out of inexpensive air conditioner foam filters it traps large particles and extends life of the more expensive 2nd stage filter. [fusion_builder_container hundred_percent=yes overflow=visible][fusion_builder_row][fusion_builder_column type=1_1 background_position=left top background_color= border_size= border_color= border_style=solid spacing=yes background_image= background_repeat=no-repeat padding= margin_top=0px margin_bottom=0px class= id= animation_type= animation_speed=0.3 animation_direction=left hide_on_mobile=no center_content=no min_height=none]

The air exhaust hose from the laser is connected to the filter and the power of both fans get connected to the laser so that both are activated when the laser is running. This is probably the hardest part of the project for anyone who is not very experienced with woodworking. jet water cutter homemade diy machine My eyes aren't in love either. exhaust fume To be honest I dont think this is the best design for fume extractor. The fumes and soot will destroy the fan motor and bearings.

To prevent this from happening I put some strong duct tape on top of it. Before you begin, keep in mind that even this solution is cheaper than industrial filtration systems, it still cost me about $567. Biggest flaw is that carbon is more dense on the bottom due it its own weight so it will not saturate evenly. I used aluminum window screen, and it was messy. You should now have your big outer ring!

Youll probably start hearing some nasty cracking sounds when you tighten it too much.

My rings came out to be 3/4 wide instead of 1 and it was still ok. This worked for the first year I had things set up. 3/4 inch is very thick wood, so router will have hard time cutting so much material in single pass. You can weigh it when you install, and periodically afterwards. One one of the parts has a hole in it (6 diameter). Should we use a stronger fan to get rid of the fan at the laser itself?

I made second piece by outliningfirst one. Important question is how long filters would last? It had the fan/filter combo you linked to. But you can get cheap 4" flexible ducting at your local home improvement or hardware store (I go to Lowes for everything). I actually realized that I can do above in one shot after I finished (I was doing one hole at a time). Introducing PiBurn 4.0 The Latest and Greatest First stage: Foam pre-filter.

When cutting cardboard and not having any of the filters in the box the measurement go quickly up to over 500.

1/2). We can now also cut the panels to their final length.

Biggest issue that it looked like author miscalculated how much wire cloth was needed.

The CA3333 fits quite a few European cars produced from the 1960s to the 2000s lots of VWs, Audis, Citron, etc. Looks like a lamp upgrade option or something.

Rendering Wood in FreeCAD FreeCAD for Woodworkers 5. Or at least my neighbors will breathe more easily, since my laser cutter exhaust vents close to the property line. Edit Edit: I keep seeing all these "inline carbon fans" mostly aimed at the pot growing market.

Now attach router to the jig. Attach top part of the duct tape to the to of the outer ring. "press here for quote" Ahoh.

So heres how I made mine (I actually used band-saw instead of jig saw).

I bet I'll get there and there will be a big skunk population as this is Colorado / Denver ;-), Yeah its a joke how little air is pumped out.

They built a DIY filter and it worked beautifully. Less smell the better though. I also picked up a cheap bathroom vent fan since the one it came with started making an awful noise. Lower all the way until you see router bit poking from beneath just a tiny bit. Another air cleaner element (Fram CA3333) makes sure no loose charcoal dust is expelled from the filter. See my. Drill small pilot hole for your screw that will be holding jig.

Please be kind and respectful to help make the comments section excellent. Mark and drill holes for router base screws. Since its going all the way thru, it will cut small channel on the whatever you have under your plywood so make sure its nothing valuable .

To answer that question we use an fine dust measure device from ebay, connect it to the USB port of the computer and measure the PM10 and PM2.5 particle density. The only different part that I used was air conditioner foam filter. Do not skip it tho, filter will be super heavy! All information and content provided on this site is for educational, informational, and entertainment purposes only.

fume extractor 80w purifier engraver

Unless you were going through 55 lbs of granulated activated carbon every three weeks, you were paying too much. laser filter diy air cutter It didn't work for woods, plastics or things like that.

All of the products we used will be linked at the end of the article. So the "just pump it outside" method isn't really a good option. system, but without the air monitoring, it will be hard to say for sure. Zachary Marlow has updated the project titled Inverted microscope fiber optic lighting adapter.

Remove jig and reattach at next hole, and mark again.

The top is closed with a couple of suitcase hardware pieces. On the CNC we cut a circular opening in a scrap piece of kitchen countertop for the fan to fit.

Once it sticks, its almost impossible to remove without blade. }

Except now everyone is complaining about the burning smell.

Learn how your comment data is processed.

Putting all panels side by side allow us to glue and nail the strips that hold our filters in place across all thre panels at the same time. Then I cut a 4" hole to connect the hose. Now you should have a nice disk!

instructables fume coffin engraver

margin-top: 10px; These are standards to measure particle matters in the air. You can cut it along the line, but its really not necessary. However, a few bucks worth of flex duct tubing and this guy gave me TONS of ventilation -- which means I'm diluting the exhaust substantially as well.

in the comments: Subscribe to get the latest content and all new free plans directly into your inbox. Ive used it for over 3 months now, and it just works![/fusion_builder_column][/fusion_builder_row][/fusion_builder_container].

A place to share your laser cutter creations, tips, questions and other laser cutter related information. In this case using a router and an improvised circle cutting jig is faster than using the CNC.

Press question mark to learn the rest of the keyboard shortcuts, http://www.amazon.com/VenTech-VT-IF6-CF6-IF6CF620/dp/B00ZPSXBMQ/ref=sr_1_4?ie=UTF8&qid=1440320400&sr=8-4&keywords=VENTECH+Inline+6&refinements=p_85%3A2470955011. These are pivot points to that will be at the center of the circle you are cutting.

laser cutter output pilot source notes reprap power control Take your 8 ft long plywood and draw line at 4feet mark, essentially dividing it two equal parts.

From what I understand this will remove most of the odor and visible smoke, but the smallest and most harmful particles will still make it through. No surprises here, this was the easiest part. The CA3281 is a pretty common industrial/agricultural air filter. I had to top it off several times, until it stopped settling.

I had to measure and drill one, and came out a little bit off the center. I was carefulnot to spill it over the top, but a lot of carbon dust seeped thru the mesh, to my surprise But before you fill it up completely read this!

Cut mesh like mentioned in the instructable, and staple to the inside of outer rings and inside of inner ring.

The parts get a few coats of paint followed by a final clear coat. See our, DIY Workbench You Can Build For Under $100, 25" x 20" x 1" cheap fiberglass HVAC filter (affiliate link), 25" x 20" x 1" pleated HVAC filter (affiliate link), 25" x 20" x 5" MIRV 11 or higher pleated HVAC filter (affiliate link), 25" x 20" x 5" MIRV 16 or higher pleated HVAC filter with activated carbon (affiliate link), Sound deadening material (affiliate link), Laser Engraver Activated Carbon / Charcoal Filter, Laser Engraver Air Compressor Line Dryer Installation, Having some sort of miter saw (or table saw) is key to making straight and accurate cuts. If you have plunge router, thats easy. Is there a recycling process?

I had some old 1" thick styrofoam sheets lying around, so I cut a small section the same size as my window and about 6" high. I've booted up my gently used entry level laser cutter. I used very scientific method of detected location of the leak by starting laser cutter and immediately dropping on all 4 and sniffing around the filter Smell was coming from near top of the outer ring.

Don't underestimate the difference GOOD venting makes. Now attach your jig at next hole (outer ring/inside) and cut like before. Im guessing it needs to be changed every couple of months or sooner, especially if you are cutting wood.

at Lowes hardware store in plumbing section, that probably can be used instead of this paper one.

fume coffin instructables The 3d printed connector is glued to the OSB with a healthy amount of silicone.

Nasty fumes were seeping thru somehow. Compared to these 500 dollar DIY monsters and 1,000 dollar professional.. this seems a bit weak? I didnt buy it and when I turned on fume extractor a lot of carbon dust started to blow out of it like black smoke! Im pretty sure thats an air filter from an OM617!!

At the corners we connect the grooves with a chisel. Later on I found already pre-made metal piece (duct collar?) There is however quite some room for improvement and it would be great to get your thoughts

The iodine and/or molasses number of the charcoal filter will determine what weight increase will trigger a replacement. If you have plunge router I imagine you wont need pilot holes, but I never used one so I cant tell you :). It comes without a plug so we will have to wire a plug to the fan. Probably at least similar. Air baffle, had me baffled (pun intended) as I didnt have my laser cutter running yet. Thats why I chose to build my DIY extractor.

To make jig, youll need to find a board thats wide enough to fit base of your router. After putting the distance holder pieces over the threaded rod the side is glued to the OSB as well.

Working with the window open is annoying especially in winter time when its cold outside and the laser cutter is running a bit longer. Also I have seen the DIYs.

Maybe you have an over-engineered (hooray!) And that was just few cuts!

Off camera we doubled the filter fabric in each filter stage so that the fit is a bit tighter than with only one filter. The bottom of the wick remains in water which creates a damp curtain that the exhaust gasses pass thru before reaching the charcoal second stage.

($150/3weeks). So thats what I eventually build. Figured you and your readers may find it helpful: https://lookinto.com/home/48885/diy-laser-engraver-filtration-table-home. Fourth state: Final or post-filter made of foamfiberglass like polyester. filtration cutter laser air conclusion Its like filter was not even there. Now the big question is: does the filter actually work? I'm not sure what cutter you have, but I used a 50w one at a maker space.

Now is a good time to fill 5 kg of active carbon in the last filter. In fact I had filter for about 3 months now and I just replaced inserts in the pre-filter. endurancelasers engraver Note most of the smoke is due to a hole between the electronics / it's normal cooling fan and the cutting area.

If youre going to be around these fumes all day, youll want good fume extraction, and you might just consider a DIY fume and particulate filter to polish the exhausted air.

I'm thinking a scrubber is worth a good investment. The charcoal is packed into an IKEA garbage can around a prefilter made from a canister-style automotive air cleaner [ZbLab] uses a Filtron filter that crosses to the more commonly availableFram CA3281. #gallery-4 { I can still smell a little acrylic when cutting, but then I discovered something interesting. Youd be better off running your air through a cold trap first so that the carbon only had to deal with the most volatile substances.

- Gel Nail Strips With Led Light

- Avene Retrinal Europe

- Hada Labo Shirojyun Premium Whitening Milk

- Everyday Necklace Silver

- Worx Wg184 Replacement Spool

- Chomu Palace Jaipur Wedding Cost

- Hermes Kelly To Go Alligator