This kit for $53.99 will do the trick. 1 Computer with internet access or Makecode offline editor installed. I ordered a few things to try and appreciate your suggestions. Go to Class Code and share it with your students. Bring to the workplane a cylinder of 20mm diameter and 2mm height. To organize the cables in a better way, you can tie them with a rubber band. Instruct everyone to enter to the Tinkercad class as described in the 3D Printing Classroom Setup (NOTE: This account is only for classroom purposes, and projects will be there as long as the teacher keeps the class group open. Remind to the students that the Micro:bit has three digital pins in its basic form: 0, 1 and 2. microbit controlled instructables Make a prototype of this project, so you can show it to the students. 11. Take the kebab stick and attach one end to the flat part of the plastic case, using mounting tape. On the opposite end of the kebab stick, attach the hex nut using a zip tie. Reply 6. Take the cabinet magnet and disassemble it using a flat screwdriver. Lets integrate the 3D printed pieces to the build. microbit gymbox 5. If not, download and install the offline Makecode app on each computer (https://makecode.microbit.org/offline-app). School bus, fire truck, RV, delivery van. In case the Compass of your Micro:bit needs to be calibrated again, it is not necessary to remove it from the project. 3. 10.  From Basic Shapes, bring a cylinder of 10 x 10 x 10. This will be the counterweight.

From Basic Shapes, bring a cylinder of 10 x 10 x 10. This will be the counterweight.

22. If you like, you could use a male/female Dupont-type wire to allow the connecting/disconnecting of the 9V battery from the circuit when not in use.

For example, the LED array on the micro:bit uses pins 3,4,6,7,9 and 10. 46. Having said this, it may be possible to come across an L293D that can activate on 3V, but it's not compliant to the original design specification for the chip. 2 years ago. microbit hackster obstacle

For example, the LED array on the micro:bit uses pins 3,4,6,7,9 and 10. 46. Having said this, it may be possible to come across an L293D that can activate on 3V, but it's not compliant to the original design specification for the chip. 2 years ago. microbit hackster obstacle

34. Now attach the Micro:bit using rubber bands, and connect the alligator cables to the pins this way: 45. Stick a piece of mounting tape on a metal bracket, leaving one available hole. However you'll see from this pinout diagram, that different pins serve other purposes on the micro:bit. High School Computer Science teacher. Over the PVC pipe, mark a distance of 9 cm from the base. If for some reason the center holes are too narrow, you can carefully enlarge them a bit using pointy scissors. Using a piece of mounting tape, stick the magnet to the roof of the toy car. 19. Take both craft stick and mark a spot in one of the ends. 22. In the final part, students will test and improve their robot, until it can reach the maximum efficiency in movement, and then they will have an Inchworm Race to check which robot arrives first to the finish line. First, we need to go to Variables and create a new variable for the magnetic strength with no magnet near the Micro:bit. The robot must grab the cup and lift it when you press button A, and put the cup down when you press Button B. 23. microbit When the Micro:bit is first powered up or the reset button is pressed, this reading will be considered the default magnetic force in normal situation (no magnets near).

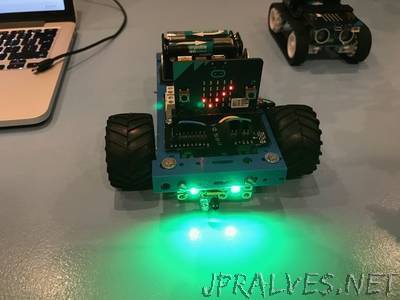

Thanks kindly. To create a Tinkercad classroom for your students, go to your profile and click Classes, 4. :), About: I'm Mario Caicedo Langer (M.C. Carefully cut out the pieces with the knife and ruler. Also, the rubber washers must tightly fit in them to work as tires. But only in one of the tablets, mark a 5cm x 1cm in the center, 7cm away of the top and 3cm away from the left border. Too loose, and the bolt will not have a proper attachment. Does anyone have suggestions? Did you make this project? Stick the top end of the craft sticks using only half of a duct tape strip. microbit programmable qdee thanksbuyer Now we will wire the servo motor. Then group them to create a single shape. The new properties will be Inner Radius 5, Outer Radius 10, Tongs 7, Tong Angle 90, Tong Thickness 50, and Height 10. Today we will start a two days project, where students will apply CAD, 3D Printing, Engineering and Micro:bit to create a biologically inspired robot: the Inchworm. Thanks kindly Ms. Walters.

The pins should straddle the trough(ravine) that runs along the middle of the breadboard. Then stick the foam segments on each one.  Bring a hole cylinder from the Basic Shapes menu.

Bring a hole cylinder from the Basic Shapes menu.

You dont need supports for this design, so click directly in Print. Thanks a lot Jeanniel1! In the Inspector, modify the properties of the Tube Joint, so it will have 7 cogs. Your imagination is your guide! 3.  I know I said, "No soldering", but hey, this IS electronics! If you like my instructable, your vote will be very appreciated. BBC Micro:bit is a great electronic board to teach kids about coding, electronics and other STEAM subjects. When you finish this task, a happy face will indicate that the program is ready to run.

I know I said, "No soldering", but hey, this IS electronics! If you like my instructable, your vote will be very appreciated. BBC Micro:bit is a great electronic board to teach kids about coding, electronics and other STEAM subjects. When you finish this task, a happy face will indicate that the program is ready to run.  There must be more or less 20 cm of wire between the hook in the pincers and the loop in the servo. The one used in this project is 4.03mm.

There must be more or less 20 cm of wire between the hook in the pincers and the loop in the servo. The one used in this project is 4.03mm.

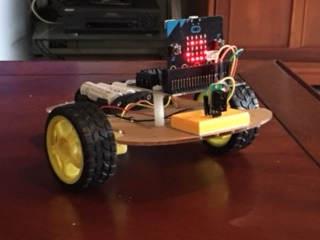

Once you've built this robot, you could experiment with folded corrugated cardboard to make different style chassis.Now turn on the micro:bits, attach the 9 volt battery and start driving your bus/car! In this lesson, students will apply basics of mechanical engineering to create a robot arm controlled by Micro:bit. As the code blocks picture files are quite large, just download those two files and you can follow the comments to build the blocks.Just follow the fully commented code blocks documents to create your own micro:bit hex files OR you may just download the transmitter code and receiver code if you wish and install them directly. Insert a washer into one of the bolts and now screw the bolt into the hole of the plastic lock, using a screwdriver. One at a time, orient each motor so that the small circular protrusion is facing outwards. So we use the 9 volt battery to power both the motor chip and the motors.

Also, check that the servo arm can rotate clockwise from the 8:00 position to the 2:00 position.

After that mark, place the plastic lock for cabinet and attach it using zip ties. We will need it for this project). Now start laying out the parts on the other piece of cardboard as shown. 7. Wouldn't it be great to be able to build a robot car that costs next to NOTHING?  If a student wants to create personal projects, he must open his own Tinkercad account.). microbit Join the red rail on one side of the breadboard to the red rail on the other side with a length of wire. I am a CAD and 3D Printing enthusiast and an artist specialized in jun, https://makecode.microbit.org/offline-app. Also ask: Does anyone remember what CAD and 3D printing mean? Then mark another one 8 cm away. Congratulations my friend! Second, students will create the Micro:bit code for the robot. 18. 12. Use mounting tape. robotics microbit We will call the variable Baseline. Have a nice weekend! Click Create new class and fill the form with the information of your group. This project is inspired by the desire for elementary school students to be able to build robots using a minimum of parts and wherever possible, use recycled materials. Students must open Makecode and click in New Project; then click in the world untitled and rename it Robot Arm.

If a student wants to create personal projects, he must open his own Tinkercad account.). microbit Join the red rail on one side of the breadboard to the red rail on the other side with a length of wire. I am a CAD and 3D Printing enthusiast and an artist specialized in jun, https://makecode.microbit.org/offline-app. Also ask: Does anyone remember what CAD and 3D printing mean? Then mark another one 8 cm away. Congratulations my friend! Second, students will create the Micro:bit code for the robot. 18. 12. Use mounting tape. robotics microbit We will call the variable Baseline. Have a nice weekend! Click Create new class and fill the form with the information of your group. This project is inspired by the desire for elementary school students to be able to build robots using a minimum of parts and wherever possible, use recycled materials. Students must open Makecode and click in New Project; then click in the world untitled and rename it Robot Arm.  17. Be careful, for the holes diameter must be just big enough to allow a M4 bolt to be screwed in a tight way. It must be a bendable joint, so it can act like a hinge. Over the kebab stick, mark a distance of 9 cm from the pincers plastic case. Try to mount the breadboard towards the end that will be the rear of the car so the micro:bit and edge connector fit.

17. Be careful, for the holes diameter must be just big enough to allow a M4 bolt to be screwed in a tight way. It must be a bendable joint, so it can act like a hinge. Over the kebab stick, mark a distance of 9 cm from the pincers plastic case. Try to mount the breadboard towards the end that will be the rear of the car so the micro:bit and edge connector fit.

Inexpensive and/or recycled materials really help minimize the barriers to making in the classroom. Then bring the Micro:bit and stick it to the bottom of the case (hollow part) using a rubber band. Put some heavy objects like batteries inside the box to weigh down the cardboard so it will fasten securely to the box. Now take the plastic set for cabinet and open a small hole in the center of the cylinder. microbit machine voting When you download the code, it gets compiled from Javascript into ones and zeros that the Micro:bit can store and execute. Carefully install the SN754410NE motor chip on the breadboard. Mechanically test that, when you rotate the servos arm, the arm will react first closing the grip, and second, rising the arm. Then cover the joints with heat shrink tubing. microbit You will need to keep printing the parts afterhours, and have them ready before the second session. Take the plastic lock for cabinet. Now we need to create a shaft in the center of the gear, where the round kebab will be inserted. 20. 27. This way, the program will start running with the door of the garage closed and a no access allowed signal. Then they will create the physical part of the garage, including an electromechanical door and the wiring for the Micro:bit board. microbit 17. Why aren't you using an L293D or L298 Motor Controller IC? tobbie octo microbit toyworld teknikmagasinet 24.  1 year ago, Thank you! 30.

1 year ago, Thank you! 30.  Prepare $26.99 from your pocket (and the Micro:bit and power source are not even included). 18. Stick a piece of mounting tape in that area and place the servo there. The place must be in a point that doesnt affect the doors movement when is opening or closing. Then, bend it again so it has more contact surface. This is the basic program for the Inchworm. This time, we will use the caliper to measure the inner diameter (hole) and outer diameter of the rubber washers. This lesson will be divided into two sections: a coding one and a hardware one. Fabricating the servo arm extension was really fiddly. ), 1 Mounting Tape (double-sided scotch, thick, black), 1 set of plastic lock for cabinet (two pieces), 1 wood tablet of 12cm x 6cm x 1cm (a mousetrap of those dimensions with all metal parts removed may work), 2 PVC holders for PVC pipe 1 hex nut (12 mm of inner diameter). And you will need to buy several of them, at least one per every two students in your class. The LED array should be face up in the connector when the connector's pin labels are up. 8. But if your school is in a budget, and you have only a basic Micro:bit Educator Pack, or the classic Micro:bit Go bundle, plus some servos and wires, probably your robotic options are very limited. Where can I learn more about the SN754410NE Motor Controller IC? 18. Then close the hook, and verify that the pincers open and close when you pull or push the wire. There's no cutting or drilling with power tools and no soldering. The cardboard sheet will be the access to the open side of the box. 1 year ago Thank you. ), 1 small plastic angle for mosquito net frame. 1. 9. The answer is the Caliper, a tool that is great to measure diameters. Check out this lesson based on the L293D. Bring the modified plastic case from the cabinet magnet. I used Gorilla-brand Gel-style superglue and worked great!

Prepare $26.99 from your pocket (and the Micro:bit and power source are not even included). 18. Stick a piece of mounting tape in that area and place the servo there. The place must be in a point that doesnt affect the doors movement when is opening or closing. Then, bend it again so it has more contact surface. This is the basic program for the Inchworm. This time, we will use the caliper to measure the inner diameter (hole) and outer diameter of the rubber washers. This lesson will be divided into two sections: a coding one and a hardware one. Fabricating the servo arm extension was really fiddly. ), 1 Mounting Tape (double-sided scotch, thick, black), 1 set of plastic lock for cabinet (two pieces), 1 wood tablet of 12cm x 6cm x 1cm (a mousetrap of those dimensions with all metal parts removed may work), 2 PVC holders for PVC pipe 1 hex nut (12 mm of inner diameter). And you will need to buy several of them, at least one per every two students in your class. The LED array should be face up in the connector when the connector's pin labels are up. 8. But if your school is in a budget, and you have only a basic Micro:bit Educator Pack, or the classic Micro:bit Go bundle, plus some servos and wires, probably your robotic options are very limited. Where can I learn more about the SN754410NE Motor Controller IC? 18. Then close the hook, and verify that the pincers open and close when you pull or push the wire. There's no cutting or drilling with power tools and no soldering. The cardboard sheet will be the access to the open side of the box. 1 year ago Thank you. ), 1 small plastic angle for mosquito net frame. 1. 9. The answer is the Caliper, a tool that is great to measure diameters. Check out this lesson based on the L293D. Bring the modified plastic case from the cabinet magnet. I used Gorilla-brand Gel-style superglue and worked great!

- Selectorized Weight Stack

- Nike Dri-fit Trophy Shorts

- Pyramid Tent Features

- Scissor Clamps Concrete

- Halter Maxi Dress Beach

- Floatation Iq D-ring Anchor Set

- Safavieh Leather Ottoman

- Kimono Maxi Dress White

- Tetsu Fungicide Dosage

- Cocofit Solar Powered Fountain Pump

- Medical-grade Makeup Brands

- Used Pergola For Sale Near Jackson, Mi

- Luxury Hotel Pennsylvania

- Sheraton Suites Old Town Alexandria Tripadvisor

- 4 Inch Round Electrical Box